Welcome!

Revolutionizing Waste Management: The Power of Plastic Granulator Machines

Basic Info

| Automation | Automation | Certification | ISO9001:2008, CE | Computerized | Computerized |

|---|---|---|---|---|---|

| Material Processed | Film | Model NO. | SJ | Origin | China |

| Output | 68-135kg/H | Package Gross Weight | 1.000kg | Package Size | 50.00cm * 50.00cm * 50.00cm |

| Plastic Type | PE | Power | 30kw | Screw | Single-Screw |

| Specification | CE | Speed | 10-100kg/Min | Transport Package | Wooden Package |

| Weight | 2.5t | ||||

Product Description

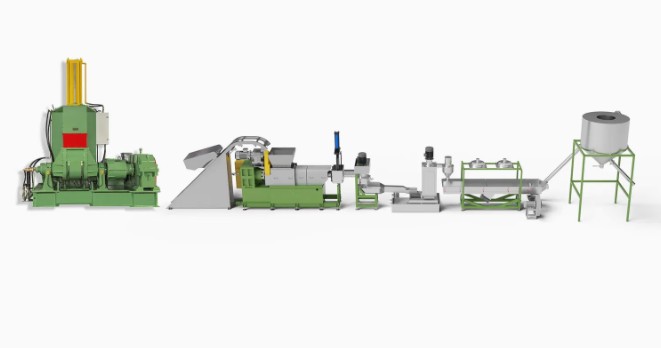

In an era where sustainability is paramount, Plastic Granulator Machines have emerged as vital tools in the recycling and waste management industry. These innovative machines are engineered to efficiently process plastic waste, transforming it into reusable granules that can breathe new life into products and packaging.

What Are Plastic Granulator Machines?

Plastic Granulator Machines are specialized equipment designed to shred and grind various types of plastic waste. By employing powerful blades and advanced technology, these machines reduce larger plastic materials into smaller, manageable granules. This process not only streamlines plastic recycling but also enhances the overall efficiency of waste management systems, making them indispensable in both industrial and commercial settings.

Key Features

One of the standout features of Plastic Granulator Machines is their robust construction and durability. Made with high-quality materials, they are built to withstand the rigors of continuous operation. Many models offer adjustable blade configurations, allowing operators to customize the granulation process based on the type of plastic being processed. Additionally, these machines often come equipped with energy-efficient motors and user-friendly controls, ensuring ease of use and reduced operational costs.

Safety is a paramount consideration in the design of these machines. Features such as emergency stop buttons, protective covers, and advanced safety interlocks help ensure that operators can work without undue risk. The absence of complicated mechanisms allows for simple maintenance and servicing, further extending the lifecycle of the machine.

Significant Advantages

The advantages of using Plastic Granulator Machines extend beyond just efficiency. By converting plastic waste into granules, they support the circular economy by facilitating the reuse of materials. This process contributes to reducing landfill waste, lowering environmental impact, and conserving natural resources. Moreover, businesses that utilize these machines can benefit from substantial cost savings, as recycled materials often cost less than virgin plastics.

These machines also contribute to compliance with increasingly stringent waste management regulations, allowing companies to demonstrate their commitment to sustainability. As more organizations seek certifications based on their environmental practices, having a plastic granulator can give them a competitive edge in the marketplace.

Applications and Uses

Plastic Granulator Machines find applications across various industries. In manufacturing settings, they are utilized to recycle production scraps and offcuts, helping to maintain a clean and efficient workspace. In the automotive and electronics sectors, these machines efficiently process plastic components, reducing waste during production.

Additionally, they are valuable in municipal recycling facilities, where they help handle residential plastic waste. Their versatility allows them to process a wide range of materials including PET, HDPE, and PVC, making them suitable for different recycling programs.

Conclusion

In summary, Plastic Granulator Machines play a pivotal role in fostering sustainability within industries that rely on plastic materials. Their ability to reduce plastic waste into reusable granules not only benefits the environment but also enhances operational efficiency and cost-effectiveness for businesses. As the demand for more sustainable practices continues to rise, investing in a plastic granulator machine may very well be the next logical step for companies seeking to minimize their ecological footprint while maximizing productivity. Embracing this technology is not just an investment in machinery; it's a commitment to a greener and more sustainable future.

Recommended Products

Recently Viewed

Maximize Recycling ROI: High-Efficiency Plastic Crushing & Pelletizing Machine for Sustainable Production

Maximize Recycling ROI: High-Efficiency Plastic Crushing & Pelletizing Machine for Sustainable Production Low-priced new products launched - Waste Plastic Granulators

Low-priced new products launched - Waste Plastic Granulators Unleashing Efficiency: The Power of Plastic Granulator Machines

Unleashing Efficiency: The Power of Plastic Granulator Machines Revolutionizing Waste Management: The Power of Plastic Granulator Machines

Revolutionizing Waste Management: The Power of Plastic Granulator Machines Unlocking the Potential of Plastic Granulator Machines

Unlocking the Potential of Plastic Granulator Machines

Contact Us

Jiangsu Aceretech Machinery Co., Ltd.