Welcome!

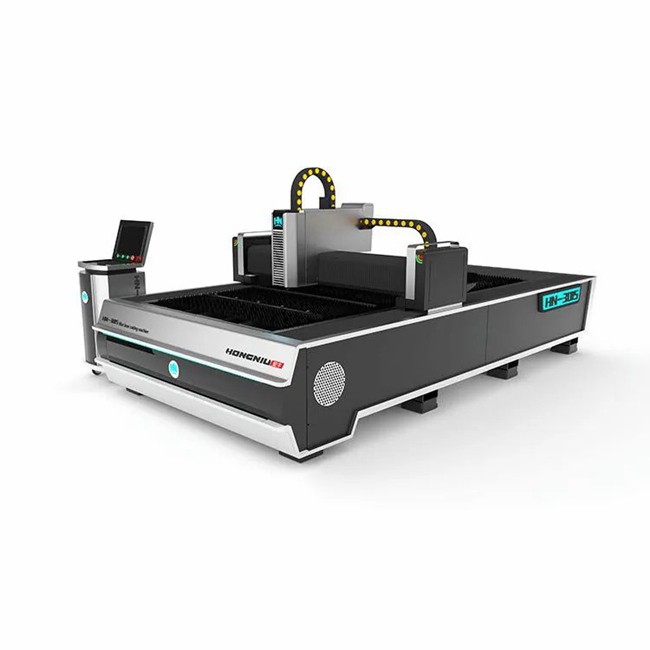

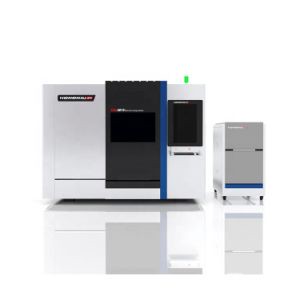

Factory Supply Mild Stainless Steel Iron Aluminum Copper Stainless Steel CNC Sheet Metal Tube Pipe Automatic Fiber Laser Cutting Machine

Product Description

Laser cutting is achieved by using the high-power density energy generated by laser focusing. Under the control of a computer, the laser is discharged through pulses to output a controlled repetitive high-frequency pulsed laser, forming a beam of light with a certain frequency and pulse width. The pulsed laser beam is transmitted and reflected through the optical path and focused on the surface of the processed object through a focusing lens group, forming fine, high-energy density light spots. The focal spots are located near the surface to be processed and melt or vaporize the processed material at high temperatures in an instant.

Laser cutting has fast speed, narrow cutting seam, small heat affected zone, good perpendicularity of cutting seam edge, smooth cutting edge, and a wide variety of materials that can be laser cut, including carbon steel, stainless steel, alloy steel, wood, plastic, rubber, cloth, quartz, ceramics, glass, composite materials, etc. With the rapid development of market economy and the rapid advancement of science and technology, laser cutting technology has been widely applied in fields such as automobiles, machinery, electricity, hardware, and electrical appliances. In recent years, laser cutting technology has been developing at an unprecedented speed, growing at a rate of 15% to 20% annually. Since 1985, China has been growing at a rate of nearly 25% per year. At present, there is still a significant gap between the overall level of laser cutting technology in China and advanced countries. Therefore, laser cutting technology has broad development prospects and huge application space in the domestic market.

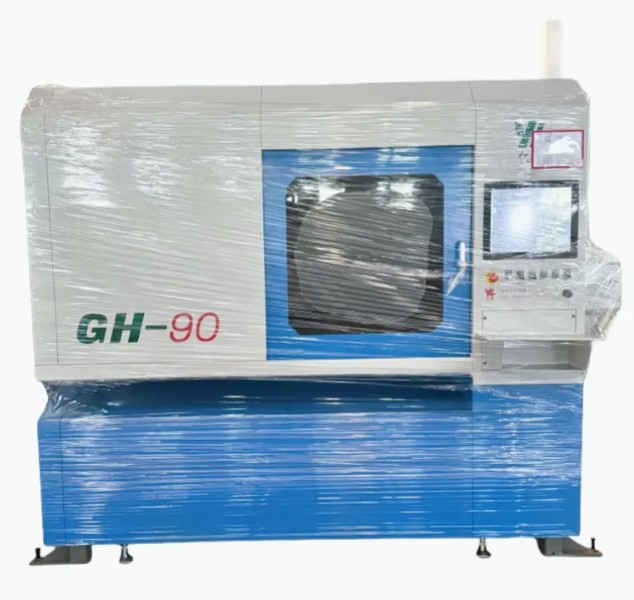

Recommended Products

Recently Viewed

Laser Cutting Machines: The Future of Custom Fabrication

Laser Cutting Machines: The Future of Custom Fabrication Laser Cutting Machines: Innovating Manufacturing with Smart Technology

Laser Cutting Machines: Innovating Manufacturing with Smart Technology Laser Cutting Machines: Precision, Speed & Versatility Redefined

Laser Cutting Machines: Precision, Speed & Versatility Redefined Laser Cutting Machines: The Future-Ready Fabrication Solution

Laser Cutting Machines: The Future-Ready Fabrication Solution The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

Contact Us

Jinan Hongniu Machinery Equipment Co., Ltd.