Welcome!

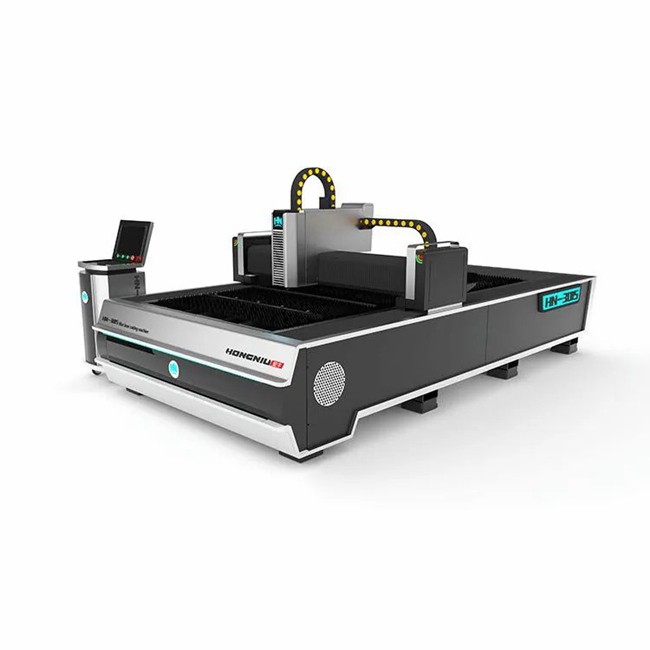

Factory Supply Fiber Laser Cutting Machine Price 1mm 5mm 20mm Stainless Steel Laser Cutting Machine

Product Description

During the cutting process of a laser cutting machine, the beam of light is focused into a small focal point through the lens of the cutting head, achieving a high power density at the focal point. The cutting head is fixed on the z-axis. At this point, the heat input by the beam far exceeds the part of the heat reflected, conducted, or diffused by the material. The material is quickly heated to the melting and vaporization temperature. At the same time, a high-speed airflow blows out the melted and vaporized material from the coaxial or non coaxial side, forming holes for material cutting. As the focus moves relative to the material, the holes form continuous narrow slits, completing the cutting of the material.

A laser cutting machine focuses the laser emitted from the laser into a high-power density laser beam through an optical path system. The laser beam irradiates the surface of the workpiece, causing it to reach its melting or boiling point, while the high-pressure gas coaxial with the beam blows away the melted or vaporized metal.

As the beam of light moves relative to the workpiece, it ultimately forms a cutting seam in the material, thereby achieving the purpose of cutting.

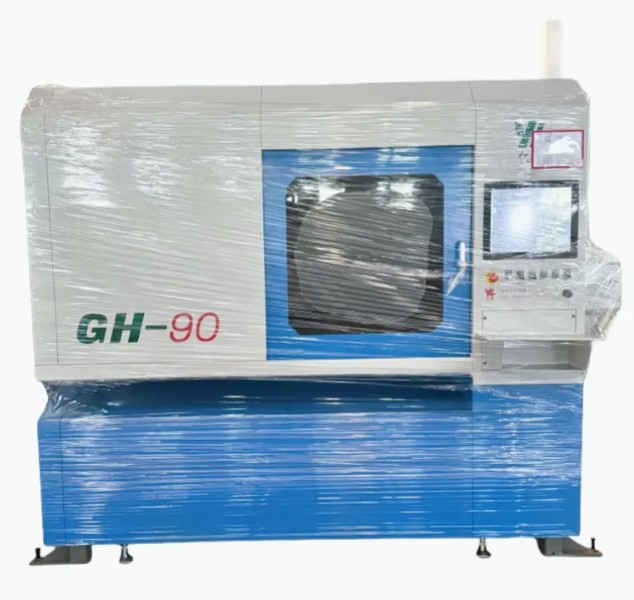

Recommended Products

Recently Viewed

Laser Cutting Machines: The Future of Custom Fabrication

Laser Cutting Machines: The Future of Custom Fabrication Laser Cutting Machines: Innovating Manufacturing with Smart Technology

Laser Cutting Machines: Innovating Manufacturing with Smart Technology Laser Cutting Machines: Precision, Speed & Versatility Redefined

Laser Cutting Machines: Precision, Speed & Versatility Redefined Laser Cutting Machines: The Future-Ready Fabrication Solution

Laser Cutting Machines: The Future-Ready Fabrication Solution The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

Contact Us

Jinan Hongniu Machinery Equipment Co., Ltd.