Welcome!

Introduction and Features of High-Precision Laser Cutting Machines

Basic Info

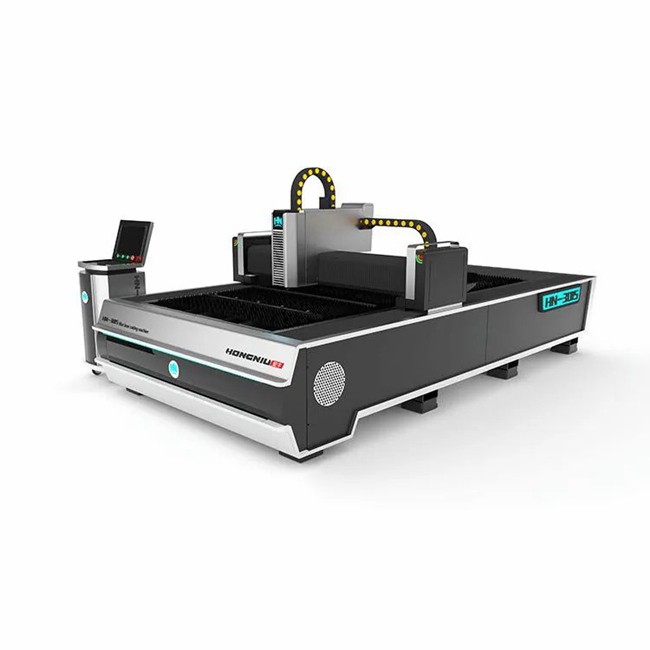

| After Warranty Service | Video Technical Support, Online Support | Applicable Material | Metal | Control System Brand | Cypcut |

|---|---|---|---|---|---|

| Cooling System | Water Cooling | Guiderail Brand | Hiwin | HS Code | 8456110090 |

| Laser Classification | Gaseous Laser | Laser Head Brand | Raytools | Laser Source Brand | Raycus/Max/Ipg |

| Laser Technology | Laser Fusion Cutting | Production Capacity | 3000/Month | Servo Motor Brand | Yaskawa |

| Specification | 3000mmx1500mm | Structure Type | Desktop | Technical Class | Continuous Wave Laser |

| Transport Package | Standard Wooden Case | ||||

Product Description

In an era where manufacturing precision and efficiency define competitive advantage, laser cutting technology emerges as a game-changing solution for industries worldwide. As global demand for complex components and customized products continues to rise, laser cutting machines have become the backbone of modern fabrication processes across multiple sectors.

How Laser Cutting Technology Works

At its core, laser cutting utilizes a focused high-power density laser beam to melt, burn, or vaporize materials with micron-level accuracy. Guided by advanced CNC systems and CAD/CAM software, these intelligent machines can execute intricate designs that traditional cutting methods simply cannot match. From aerospace-grade titanium to delicate fabrics, modern fiber laser cutters handle an unprecedented range of materials, including:

Metals (steel, aluminum, copper)

Plastics and composites

Wood and acrylics

Glass and ceramics

Textiles and leather

Key Advantages Over Conventional Methods

Sub-millimeter Precision: Achieve cutting tolerances as tight as ±0.05mm for perfect repeatability

Contactless Processing: Eliminate material contamination and tool wear

45% Faster Production: Typical cutting speeds reach 40m/min for thin materials

Multi-material Versatility: Seamlessly switch between different materials without tool changes

10-15% Material Savings: Optimized nesting software minimizes waste

24/7 Automation Ready: Fully compatible with Industry 4.0 smart factories

Industry-Specific Applications

Automotive Manufacturing

From intricate gear components to EV battery casings, laser cutters ensure flawless consistency for mission-critical parts.

Electronics Production

Create precision-cut circuit board templates and micro-components with heat-affected zones under 0.1mm.

Architectural Modeling

Fabricate complex metal façades and decorative elements with perfect edge quality.

Medical Equipment

Produce surgical instruments and implant prototypes meeting stringent ISO 13485 standards.

Choosing Your Laser Cutting Solution

When selecting a laser cutting system, consider these critical factors:

Power Output: Range from 500W for thin materials to 12kW+ for heavy industrial use

Work Area Size: Standard models offer 1.5×3m beds, customizable up to 6×20m

Cooling Systems: Air-cooled (compact) vs water-cooled (high-power continuous operation)

Software Ecosystem: Look for intuitive interfaces with AI-powered nesting algorithms

Safety Certifications: Ensure CE, FDA, and OSHA compliance

Why Partner With us?

About HongNiu Laser: Since 2012, the premium OEM factory has been offering a 3-year warranty. The manufacturer assesses independent third-party R&D capabilities for customization, high-performance manufacturing capacities, and professional certifications and approvals.

1. Technical R&D:Environmental Advantage : Dust-free Quiet Environmental Friendly.

2. Customer Service Advantage:7*24H fast response service.

3. Free Training:free complete standarized training on machine operation to HongNiu traning center.

4.Timely delivery. Each machine is arranged with assembly precise steps without any delay.

5.After-sales services and Guarantee. We offer 2 years warranty. If any problem happens during the period, we are responsible to solve. And if any part of the machine is broken, this situation rarely occurs.

6.Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

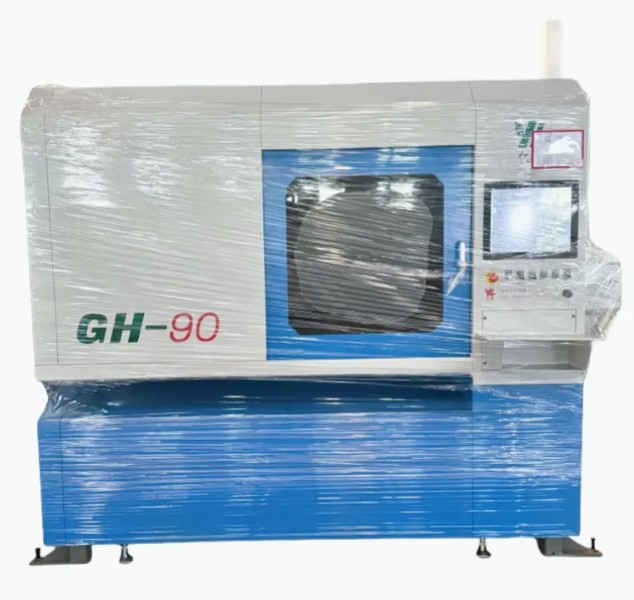

Recommended Products

Recently Viewed

Laser Cutting Machines: The Future of Custom Fabrication

Laser Cutting Machines: The Future of Custom Fabrication Laser Cutting Machines: Innovating Manufacturing with Smart Technology

Laser Cutting Machines: Innovating Manufacturing with Smart Technology Laser Cutting Machines: Precision, Speed & Versatility Redefined

Laser Cutting Machines: Precision, Speed & Versatility Redefined Laser Cutting Machines: The Future-Ready Fabrication Solution

Laser Cutting Machines: The Future-Ready Fabrication Solution The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

Contact Us

Jinan Hongniu Machinery Equipment Co., Ltd.