Welcome!

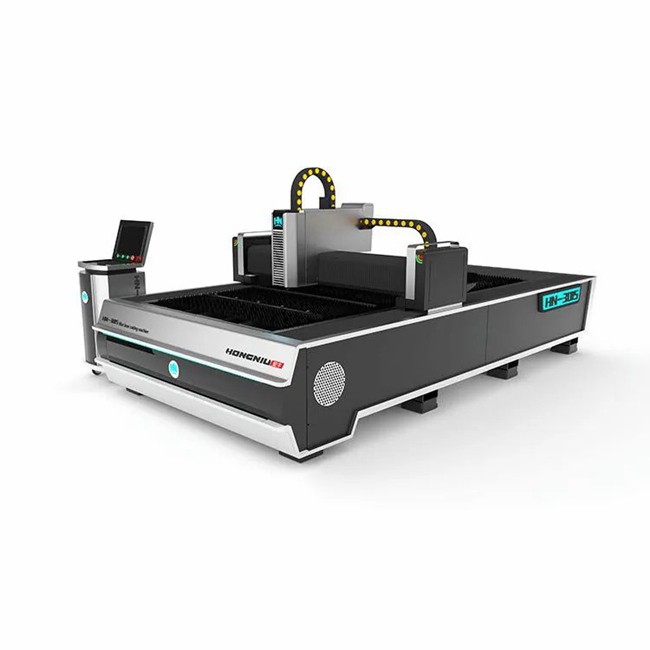

A small desktop CO2 laser cutting machine suitable for wood, leather, plastic and glass

Basic Info

| Automatic Grade | Automatic | Configuration | Customized | Cooling System | Water Cooling |

|---|---|---|---|---|---|

| Cutting Speed | 1---800mm/S | Dimension(L*W*H) | 1100*720*270mm | Engraving Thickness | 1----5mm(as The Case May Be) |

| Laser Head Brand | Customized | Laser Type | CO2 | Repeated Positioning Accuracy | 0.01mm |

| Type | Oscillating Mirror | Warranty of Core Components | 1 Year | Weight (Kg) | 60 Kg |

Product Description

Plastic laser cutting machines have become indispensable tools in industries requiring flawless and high-speed processing of polymer-based materials. Combining advanced optics with intelligent software, these systems deliver unmatched accuracy for prototyping, mass production, and custom designs.

How Plastic Laser Cutting Works

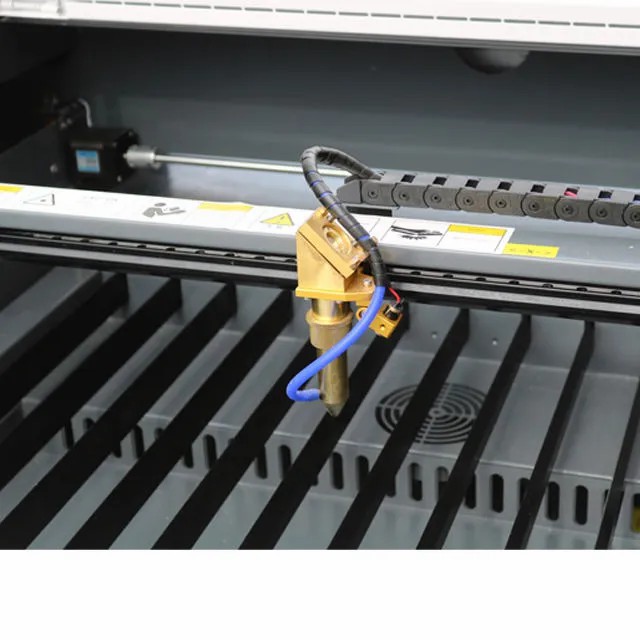

Using a focused CO2 or fiber laser beam (9.3–10.6 μm wavelength optimized for plastics), the machine vaporizes material along programmed paths with pinpoint accuracy. Non-contact technology eliminates mechanical stress, while integrated exhaust systems safely remove fumes. Compatible materials include:

Acrylic (PMMA)

Polycarbonate (PC)

ABS

PET/PETG

Nylon

PVC (with proper ventilation)

Foam and composite sheets

Key Advantages Over Traditional Plastic Cutting Methods

Micro-Precision: Achieve intricate cuts as narrow as 0.1mm with ±0.05mm tolerance.

Smooth, Sealed Edges: Laser heat polishes cuts instantly, eliminating post-processing for many applications.

3x Faster Production: Cut speeds up to 25m/min for thin plastics (1–5mm thickness).

Zero Tool Wear: No blades or bits to replace, reducing long-term costs.

Material Efficiency: AI-powered nesting software reduces waste by 20–30%.

Hygienic Processing: No coolant or lubricants required, ideal for medical/food-grade components.

Industry Applications

Signage & Displays: Create flawless acrylic lettering and LED light guides.

Automotive: Cut dashboards, interior trim, and sensor housings without burrs.

Electronics: Precision-cut insulators, circuit board masks, and device casings.

Medical: Produce biocompatible components with sterilizable edges.

Packaging: Prototype molds and cut custom plastic clamshells.

Why Choose a Dedicated Plastic Laser Cutter?

While universal lasers work across materials, machines engineered specifically for plastics offer:

Wavelength Optimization: CO2 lasers (9.3–10.6μm) maximize absorption for cleaner cuts.

Dynamic Focus Control: Maintain beam consistency on warped or uneven sheets.

Low-Odor Operation: Advanced filtration systems for PVC and other fume-prone materials.

Warp Prevention: High-speed pulsing minimizes heat buildup in thin sheets.

Technical Highlights

Power Range: 40W–300W (ideal for 1–25mm thickness)

Work Area: Standard 600x900mm to large-format 1300x2500mm beds

Positioning Speed: Up to 100,000mm/s

Software: Compatible with AutoCAD, CorelDraw, and ERP systems

Future-Ready Features

IoT Connectivity: Monitor job progress remotely via smartphone.

Automated Material Handling: Integrated conveyor systems for 24/7 production.

Eco Mode: Reduce energy use by 40% during idle times.

Why Choose Us?

About HongNiu Laser: Since 2012, the premium OEM factory has been offering a 3-year warranty. The manufacturer assesses independent third-party R&D capabilities for customization, high-performance manufacturing capacities, and professional certifications and approvals.

1. Technical R&D:Environmental Advantage : Dust-free Quiet Environmental Friendly.

2. Customer Service Advantage:7*24H fast response service.

3. Free Training:free complete standarized training on machine operation to HongNiu traning center.

4.Timely delivery. Each machine is arranged with assembly precise steps without any delay.

5.After-sales services and Guarantee. We offer 2 years warranty. If any problem happens during the period, we are responsible to solve. And if any part of the machine is broken, this situation rarely occurs.

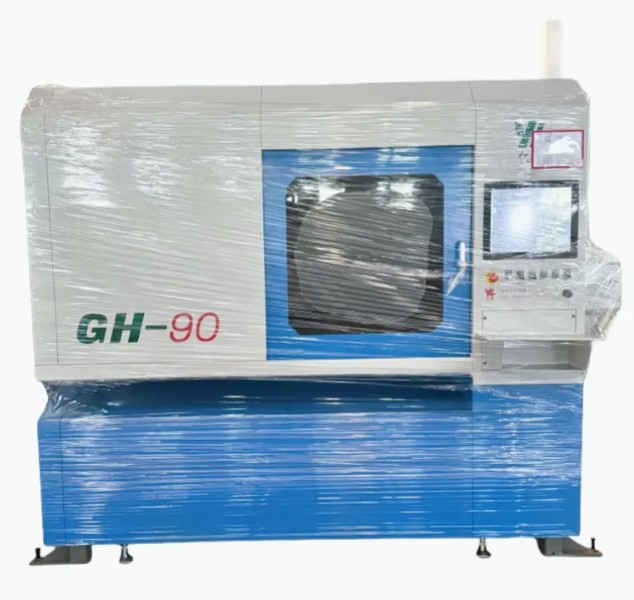

6.Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

Recommended Products

Recently Viewed

Laser Cutting Machines: The Future of Custom Fabrication

Laser Cutting Machines: The Future of Custom Fabrication Laser Cutting Machines: Innovating Manufacturing with Smart Technology

Laser Cutting Machines: Innovating Manufacturing with Smart Technology Laser Cutting Machines: Precision, Speed & Versatility Redefined

Laser Cutting Machines: Precision, Speed & Versatility Redefined Laser Cutting Machines: The Future-Ready Fabrication Solution

Laser Cutting Machines: The Future-Ready Fabrication Solution The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

Contact Us

Jinan Hongniu Machinery Equipment Co., Ltd.