Welcome!

Laser Cutting Machines: The Future of Custom Fabrication

Basic Info

| Applicable Material | Nonmetal | Application | Home Appliance, Textile Machinery, Shoemaking Industry, Woodwork Industry, Advertising Industry | Cooling System | Water Cooling |

|---|---|---|---|---|---|

| Laser Classification | Gaseous Laser | Laser Technology | Laser Fusion Cutting | Model NO. | JG001 |

| Name | Fabric Laser Cutting Machine | Origin | China | Package Gross Weight | 1400.000kg |

| Package Size | 320.00cm * 220.00cm * 190.00cm | Specification | 1000kg | Structure Type | Gantry Type |

| Technical Class | Continuous Wave Laser | Transport Package | 300X200X134 cm | ||

Product Description

Product Overview

Laser cutting machines are revolutionizing the way industries approach design and production. These cutting-edge systems utilize focused laser beams to deliver precision cutting, engraving, and marking across an expansive range of materials, including metals, plastics, wood, textiles, ceramics and more. Designed for both industrial and creative applications, they combine advanced optics, intelligent software, and robust engineering to cater to sectors such as automotive, aerospace, consumer goods, architecture, and bespoke craftsmanship.

Equipped with adaptive laser sources (fiber for metals, CO₂ for non-metals), these machines effortlessly handle thicknesses from paper-thin foils to dense metal plates. Their computer-guided precision ensures flawless execution of even the most intricate designs, while programmable settings allow rapid transitions between materials and tasks. With compatibility for 3D cutting and real-time adjustments, laser cutting machines are redefining efficiency in prototyping, small-batch production, and high-volume manufacturing.

Standout Benefits

1. Micron-Level Accuracy

Achieve cuts with tolerances as precise as ±0.05 mm, perfect for aerospace components, microelectronics, and medical devices. The laser’s consistency ensures identical results across thousands of units.

2. Zero Tooling Costs

Eliminate dies, molds, or blades. Digital designs are directly translated into cuts, slashing setup time and expenses for custom or evolving projects.

3. Multi-Functional Capability

One machine performs cutting, engraving, etching, perforation, and marking, streamlining workflows and reducing equipment investments.

4. Energy Efficiency

Modern systems consume up to 30% less energy than conventional cutting tools with idle modes and smart power management to reduce operational costs.

5. Minimal Material Contamination

Non-contact processing prevents mechanical stress or residue, critical for food-grade packaging, medical tools, and optical components.

6. Rapid Prototyping

Turn digital concepts into physical parts within hours, accelerating product development cycles and enabling faster market entry.

7. Cloud Connectivity

Access machine controls, design libraries, and performance analytics from any device. Over-the-air updates keep systems aligned with the latest software advancements.

Industry-Specific Solutions

1. Automotive: Craft lightweight chassis parts, gaskets, and EV battery components with flawless fitment.

2. Home Decor: Produce intricate metal screens, wooden inlays, or personalized acrylic lighting fixtures.

3. Agriculture: Durable stainless steel parts for machinery, tags for livestock, or custom irrigation components.

4. Education: Enable students to prototype robotics parts, architectural models, or art installations.

5. Retail: Create eye-catching acrylic displays, engraved promotional items, or bespoke signage.

Why Laser Cutting Stands Out?

Laser cutting machines empower businesses to transcend traditional manufacturing limitations. By merging digital agility with industrial-grade performance, they reduce waste, enhance design freedom, and support sustainable practices. Whether you’re a startup exploring new markets or an enterprise optimizing supply chains, laser technology offers scalable solutions that grow with your ambitions.

About Us

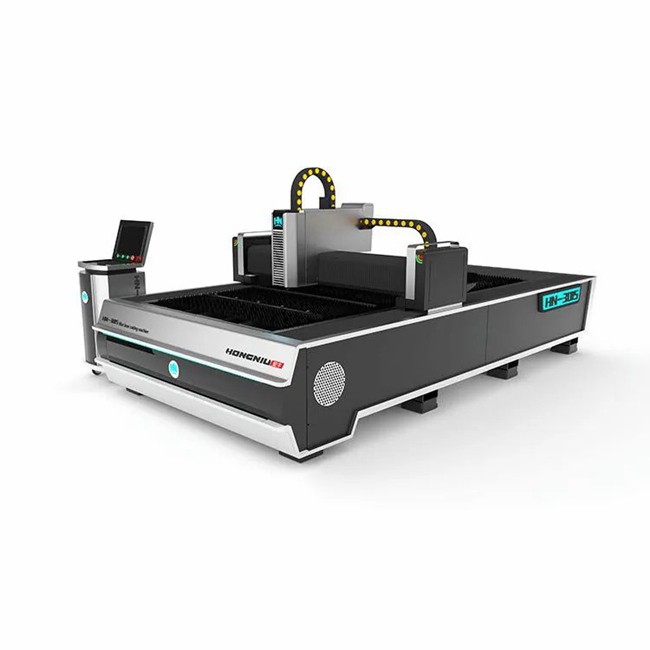

Jinan Hongniu Machinery Equipment Co., Ltd. is a trusted manufacturer and supplier of high-quality industrial machinery and equipment based in Jinan, China, specializing in the design, production, and distribution of robust machinery solutions for construction, mining, agriculture, and material handling industries. Leveraging advanced technology, a skilled engineering team, and stringent quality control systems, the company delivers durable, efficient, and cost-effective equipment tailored to meet global client needs while adhering to international standards and certifications. Committed to innovation, customer-centric service, and sustainable practices, Jinan Hongniu has established long-term partnerships worldwide, offering customized solutions, timely technical support, and reliable after-sales services to enhance operational productivity across diverse sectors.

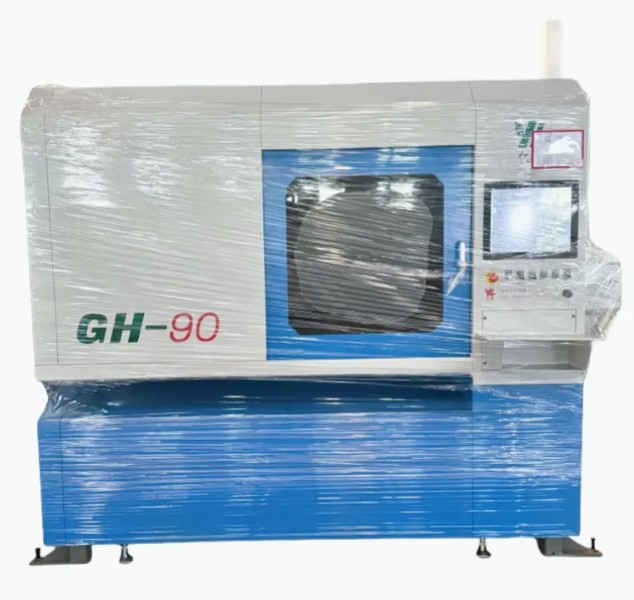

Recommended Products

Recently Viewed

Laser Cutting Machines: The Future of Custom Fabrication

Laser Cutting Machines: The Future of Custom Fabrication Laser Cutting Machines: Innovating Manufacturing with Smart Technology

Laser Cutting Machines: Innovating Manufacturing with Smart Technology Laser Cutting Machines: Precision, Speed & Versatility Redefined

Laser Cutting Machines: Precision, Speed & Versatility Redefined Laser Cutting Machines: The Future-Ready Fabrication Solution

Laser Cutting Machines: The Future-Ready Fabrication Solution The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

The Indispensable Power of Precision: Your Guide to Modern Laser Cutting Machines

Contact Us

Jinan Hongniu Machinery Equipment Co., Ltd.