Welcome!

full auto continuous tyre pyrolysis plant

Update time:2022-02-15 16:09:27

Price:$ 150000 - $ 280000 / Unit

Min Order:1 Unit / Units Unit

- T/T MoneyGram

- china port

- 2 Unit / Units per Month

Basic Info

| After-sales Service Provided | Engineers available to service machinery overseas | Brand Name | YIBO | Condition | New |

|---|---|---|---|---|---|

| Model Number | Gw 25T | Place of Origin | Shandong, China | ||

Product Description

Product Description

Product Details

Product Introduction

Full auto continuous scrap tire pyrolysis production line 20 tons capacity

Brief Descriptions of the Industrial Continuous Scrap

Tire Pyrolysis Production Line (Gw 20T)

The Industrial Continuous Scrap Tire Pyrolysis Production Line(Gw 20T) is a new series researched and developed by our company according to customers’ requirement,which is based on our company’s independent intellectual property of the Full Automatic Industrial Continuous Scrap Tire Pyrolysis Production Line(Gw 15T). The Gw 20Tproduction line all-around absorbs Gw 10T production line’s safety, environmental protection and efficiency characters, adopting controllable mixed hot wind and heating recycling system. Fast start-up, stable working performance, thus greatly reduced running cost and customers’ investment cost.

The Industrial Continuous Scrap Tire Pyrolysis Production Line utilizes advanced technique technology, which split scrap tire into liquid fuel oil, carbon black and little incondensable gas. It adopts reasonable technology and equipment design, while the procession were taken in a whole obturation reactor and thus eliminating the environment pollution, realizing energy recycling and achieving admirable environmental, social and economic benefit.

Tire Pyrolysis Production Line (Gw 20T)

The Industrial Continuous Scrap Tire Pyrolysis Production Line(Gw 20T) is a new series researched and developed by our company according to customers’ requirement,which is based on our company’s independent intellectual property of the Full Automatic Industrial Continuous Scrap Tire Pyrolysis Production Line(Gw 15T). The Gw 20Tproduction line all-around absorbs Gw 10T production line’s safety, environmental protection and efficiency characters, adopting controllable mixed hot wind and heating recycling system. Fast start-up, stable working performance, thus greatly reduced running cost and customers’ investment cost.

The Industrial Continuous Scrap Tire Pyrolysis Production Line utilizes advanced technique technology, which split scrap tire into liquid fuel oil, carbon black and little incondensable gas. It adopts reasonable technology and equipment design, while the procession were taken in a whole obturation reactor and thus eliminating the environment pollution, realizing energy recycling and achieving admirable environmental, social and economic benefit.

The whole production line can be divided into six sections:

1.Fixed temperature heating system;

2.Continuous pyrolysis system;

3.Carbon black production system;

4.Exhaust scrubbing system;

5.Gas purification system;

6.Control system.

1.Fixed temperature heating system;

2.Continuous pyrolysis system;

3.Carbon black production system;

4.Exhaust scrubbing system;

5.Gas purification system;

6.Control system.

The working process of the Industrial Continuous Scrap Tire Pyrolysis Production Line is: The scrap tire, will be shredded into suitable tire chips for pyrolysis reaction (<50×50mm), and then the tire chips will be constantly conveyed to pyrolysis reactor with low temperature sulfur removal catalyst via the feeder extruder to carry through a normal pressure low temperature pyrolysis reaction. After being fractionated and cooled by the oil separator, will create fuel oil and little combustible gas. The combustible gas will be recycled to pyrolysis heating system once it has been passed through the exhaust scrubbing system. Meanwhile, the hot wind provides heating for the pyrolysis reactor, which via hot wind recycling system returns to the pyrolysis reactor for the recycling use thus can greatly economize energy consumption and reduce the equipment’s running cost.

After magnetic separation, the solid pyrolysis outcome–raw carbon black will be automatically sent to the carbon black production system and after processions such as grinding,chelating , reduction and packaging, the refined procession for carbon black will be completed.

Gases that produced in the heat supply system will be discharged at the required standard after the gas clarification system.

The Industrial Continuous Scrap Tire Pyrolysis Production Line has the following characters:

1. The advanced fixed temperature heating system and gas heating recycling system not only realizes dynamic heat supplying, heat suffering, equal pyrolysis material heat suffering, temperature adjustment and controllable but also achieves gas heating recycling, high thermal efficiency, energy saving and reducing running cost.

2. The advanced low temperature catalyzing pyrolysis technique which utilizes low temperature sulfur removal catalyst helps a thorough material pyrolysis at a low temperature. High oil yield rate(45-50%), low gas yield rate (2-4%),the colloid and bitumen contents in oil product is low and the quality of them are superior. The low pyrolysis temperature allows no coke inside the equipment and high quality carbon black outcome.

3. Since the pyrolysis temperature is far less than the operation temperature of the equipment itself and the heat suffering is equal, safety performance and equipment lifespan are greatly enhanced.

4. Industrial continuous production, the equipment performance is stable and high working efficiency.

5. The exhaust can be fully recycled to the heating system after multilevel scrubbing processions.

6. Temperature and wind amount of the gas clarification system can be automatically adjusted and controlled. The gas absorbent has strong adsorb ability and other characters such as high absorption speed, high separation speed, easily regenerated and the ability of eliminating all the contaminants in the gas, such as H2S、CL2、CO、CO2、SO2、SO3、NOX、CS2、NH3、oil and other organic compounds and solid particulates. Therefore the emission parameters will meet the emission standard of any developed industrial country.

The Industrial Continuous Scrap Tire Pyrolysis Production Line with characters of continuous production, high working efficiency, excellent safety performance, environmental protection performance, social benefit and economic benefit, thus can be widely applied in the industrial production.

Ⅳ. Technical Profile

After being shredded, the entire scrap tire will be shredded into suitable tire chips for pyrolysis reaction (<50×50mm), and then the tire chips will be constantly transported to the pyrolysis reactor together with the low temperature sulfur removal catalyst via the automatic feeder and hot seal device. The recycled hot wind in the remote fixed temperature system will be continuously sent through the high temperature pump to the pyrolysis reactor to circularly heat the material. Material will have a fixed temperature pyrolysis reaction under a fixed temperature that has been set before. The whole reaction is as following:

nCH2=C—CH=CH2

CH3 catalyst

(or SR、SBR、BR、IR、IIR、 350-440℃

CR、NBR、EPM) normal/micro negative pressure

n[C+H2+CH4+C2H4+C2H6+C3H8+C3H6+C4H8+C4H10+C5H10+C5H12+C6H6+C7H8+ …

+C12H24+C12H26+……+C20H40+C20H42+……+C25H52]

Among them:C is carbon black

H2+CH4+C2H4+C2H6+C3H8+C3H6+C4H8+C4H10 is the incondensable gas;

C5H10——C12H24 are the light oil components;

C12H26——C20H42 are the diesel components;

>C20H42 is the heavy oil component(in the second pyrolysis will be the mild carbon component)

After cooling, oil and exhaust will become light oil component, diesel component and incondensable gas. The incondensable gas after going through the scrubbing tower will be transferred to the furnace for burning and the exhaust produced in the gas clarification system will be discharged at the required standard.

The solid outcome of rubber pyrolysis reaction – crude carbon black will become the finished carbon black product after processions of the magnetic separation, ultrafine grinding, chelating, reduction and finished product packing etc.

Product Parameters

Product Details Show

Why Choose Us

About us

1,1, the company professional to produce all kinds of pyrolysis machine to convert scrap tire to diesel fuels.

Equipment & technology

2, the quality of diesel fuel and production is the biggest supplier industry

Service

3, stable product quality , supply, the good faith management

Product Processing

Product Packing

Main Products

10 TONS TO 20TONS CONTINUOUS PYROLYSIS PRODUCTION LINE

Mid. Order: ONE SET

FOB Price: US $ 280000 TO 1200000

10 TONS TO 20TONS CONTINUOUS WASTE OIL/PYROLYSIS OIL/CRUDE OIL DISTILLATION PLANT

Mid. Order: ONE SET

FOB Price: US $ 180000 TO 280000

10 TONS SEMI CONTINUOUS INDUCTION HEATING PYROLYSIS PRODUCTION LINE

Mid. Order: ONE SET

FOB Price: US $180000 TO 280000

BATCH PYROLYSIS PRODUCTION LINE 6 TONS TO 10 TONS

Mid. Order: ONE SET more cheaper FOB Price: US $ 45000 TO 60000

SEMI CONTINUOUS 8 TONS TO 12 TONS PYROLYSIS PRODUCTION LINE

Mid. Order: ONE SET more cheaper FOB Price: US $ 60000 TO 80000

SCRAP PLASTIC PYROLYSIS PRODUCTION LINE

Mid. Order: ONE SET more cheaper FOB Price: US $150000 TO 280000

Recommended Products

Recently Viewed

3 Inches 400MT Aluminum Profiles Extrusion Press Machine, Aluminum Profiles Extrusion Press Machine Manufacturer

3 Inches 400MT Aluminum Profiles Extrusion Press Machine, Aluminum Profiles Extrusion Press Machine Manufacturer 3 Inches 400MT Aluminum Profiles Extrusion Press Machine, Aluminum Profiles Extrusion Press Machine Manufacturer

3 Inches 400MT Aluminum Profiles Extrusion Press Machine, Aluminum Profiles Extrusion Press Machine Manufacturer Wire mesh machine,fence machine,wire mesh making machine

Wire mesh machine,fence machine,wire mesh making machine Resource Utilization of Steel Plan Dust-High-Efficiency Rotary Kiln Solution Industry Pain Points

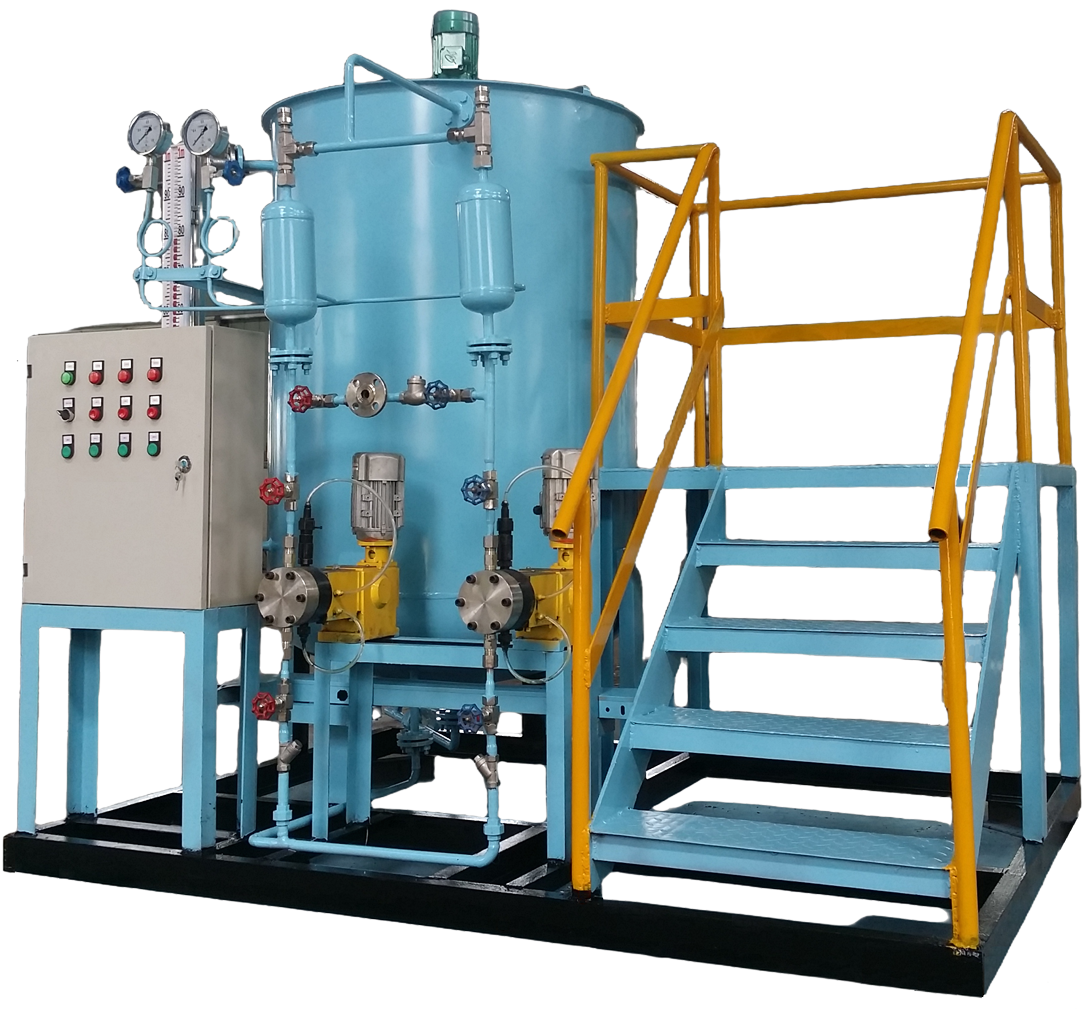

Resource Utilization of Steel Plan Dust-High-Efficiency Rotary Kiln Solution Industry Pain Points Dosing Device;Water treatment dosing unit

Dosing Device;Water treatment dosing unit

Contact Us

HOI HING LOONG SDN. BHD.