Welcome!

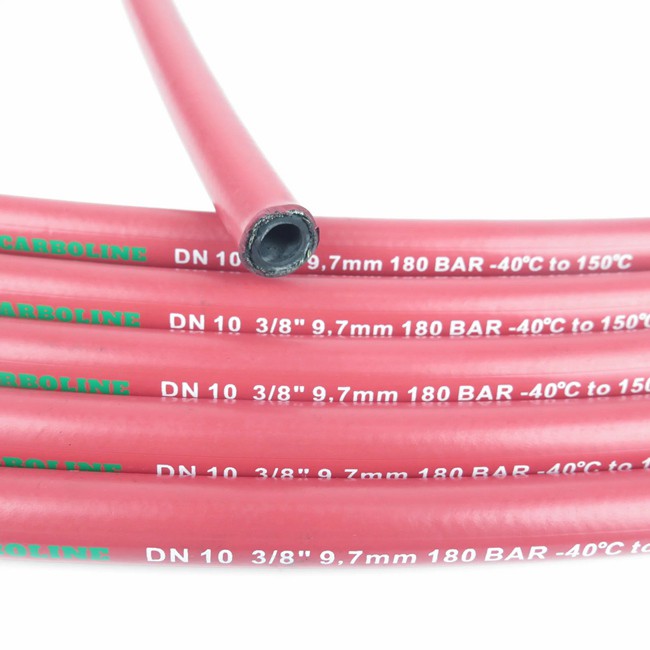

Low Price High Temperature Steel Wire Braided Reinforced Flexible Synthetic Rubber Steam Hose Pipe

Product Description

Selecting the right steam hose for a particular application requires consideration of a number of factors, including

Temperature and Pressure Requirements: Ensure that the steam hose is capable of meeting the operating conditions of the application.

Chemical compatibility: Verify that the hose material is compatible with any chemicals or substances it may come into contact with.

Flexibility and Durability: Selecting a hose that provides the necessary flexibility for installation and use, while also being able to withstand the rigors of the environment.

Steam hose is generally composed of three parts: the inner rubber layer, the intermediate layer and the outer rubber layer. The inner rubber layer is made of synthetic rubber with excellent heat resistance, such as EPDM (EPDM), which enables the transport medium to withstand pressure and protects the intermediate layer from erosion. The intermediate layer is usually braided wire or braided steel wire, used to strengthen the pressure range of the hose, improve strength and wear resistance. The outer layer, also made of synthetic rubber with excellent heat resistance, protects the inner and intermediate layers from external damage and provides additional protection.

Recommended Products

Recently Viewed

Factory Direct PTFE Tube Plastic Pipe Extruding PTFE Hose

Factory Direct PTFE Tube Plastic Pipe Extruding PTFE Hose High Quality Industrial Grade Wear Resistant Plastic Pipe

High Quality Industrial Grade Wear Resistant Plastic Pipe Wholesale Industrial Grade Wear Resistant Plastic Pipe

Wholesale Industrial Grade Wear Resistant Plastic Pipe Factory Direct White PTFE Tube China Hose High Temperature Flexible Hose Pipe

Factory Direct White PTFE Tube China Hose High Temperature Flexible Hose Pipe High Quality High Pressure Systems PTFE Material Tube Te Flon Hose

High Quality High Pressure Systems PTFE Material Tube Te Flon Hose

Contact Us

VELON INDUSTRIAL INC.