Welcome!

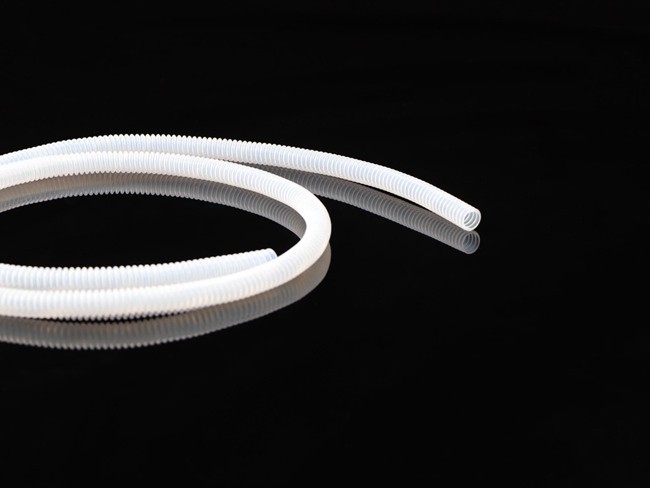

Wholesale PTFE Tube Plastic Pipe Extruding PTFE Hose

Product Description

PTFE corrugated pipes can maintain stable performance within a wide temperature range of -200 ℃ to+260 ℃, and in some cases can even withstand higher temperatures. Due to the low friction coefficient of PTFE material, PTFE corrugated pipes have good self-lubricating properties, reducing the resistance when transporting fluids and extending their service life. It will not burn in the air and meets strict fire safety requirements for use in places.

PTFE corrugated pipe is a special type of pipe made of polytetrafluoroethylene material. Flexible plastic hose is a pipeline material with various excellent properties and wide applications. During use, it is necessary to pay attention to selecting appropriate materials and specifications, and follow the correct usage and maintenance methods to ensure its normal operation and extend its service life.

Attention

Select appropriate hose materials and specifications based on specific usage environments and requirements.

Avoid excessive bending and twisting of the hose during use to prevent damage to its structure and performance.

Regularly check the connection and sealing of the hose to ensure no leakage or looseness.

Avoid exposing the hose to high temperatures, strong radiation, and corrosive environments to prevent accelerated aging and damage of the hose.

PTFE hose, as a high-performance pipeline material, plays an important role in multiple industries due to its excellent chemical stability, high and low temperature resistance, low friction coefficient, and electrical insulation properties. With the continuous development of industrial technology, the application scope of PTFE hoses will continue to expand. Due to its excellent flexibility, easy installation, and small space occupation, PTFE hoses can greatly save space.

The manufacturing process of PTFE hoses mainly includes steps such as raw material preparation, extrusion molding, cooling and shaping, cutting and processing, finished product inspection, and packaging and warehousing. High purity polytetrafluoroethylene resin is selected as the raw material, dried for later use, and processed into tubular blanks through extrusion molding and cooling shaping processes. After cutting and finished product inspection, qualified finished products are packaged and stored.

Recommended Products

Recently Viewed

Factory Direct PTFE Tube Plastic Pipe Extruding PTFE Hose

Factory Direct PTFE Tube Plastic Pipe Extruding PTFE Hose High Quality Industrial Grade Wear Resistant Plastic Pipe

High Quality Industrial Grade Wear Resistant Plastic Pipe Wholesale Industrial Grade Wear Resistant Plastic Pipe

Wholesale Industrial Grade Wear Resistant Plastic Pipe Factory Direct White PTFE Tube China Hose High Temperature Flexible Hose Pipe

Factory Direct White PTFE Tube China Hose High Temperature Flexible Hose Pipe High Quality High Pressure Systems PTFE Material Tube Te Flon Hose

High Quality High Pressure Systems PTFE Material Tube Te Flon Hose

Contact Us

Qinghe Deying Auto Parts Co., Ltd.