Welcome!

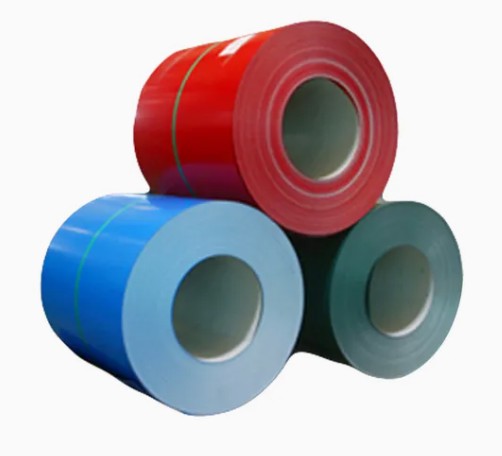

high strength hot rolled steel strip wholesale price

Product Description

high strength hot rolled steel strip wholesale price

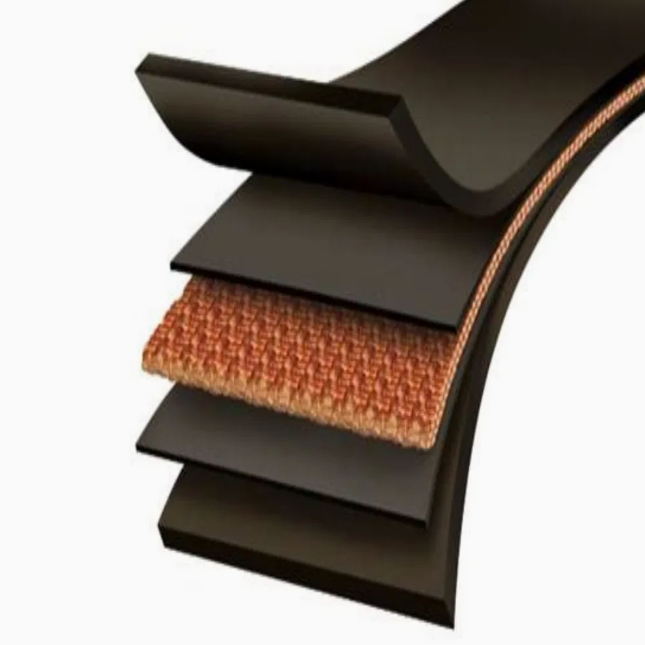

Hot rolled strip generally refers to coiled strip with a thickness of 1 to 20 mm and a width of 600 to 2000 mm. Hot rolled strip can be used directly as hot rolled steel plate, or it can be supplied as cold rolled strip as billet. It is widely used in industrial sectors such as automobiles, motors, chemicals, and shipbuilding. It is also used as billet for cold rolling, welded pipes, and cold-bent steel production. The hot strip rolling mill is the main equipment for producing hot rolled strip, and has the advantages of high production efficiency, high output, and good quality.

The price of hot-rolled strip steel is 3160.00 yuan/ton on September 6, 2024.

The price of hot-rolled strip steel is affected by many factors, including market demand, supply, cost, and domestic and foreign economic conditions. Recently, the market price of hot-rolled strip steel has shown a fluctuating trend. On the one hand, affected by the domestic and foreign economic environment, market demand has fluctuated; on the other hand, on the supply side, some steel mills have adjusted their production plans, affecting the market supply. In addition, cost factors are also one of the important factors affecting prices, including raw material costs, transportation costs, etc.

From the market trend, the price of hot-rolled strip steel may fluctuate in the short term, but in the long run, with the recovery of the economy and the stabilization of demand, the price is expected to remain relatively stable. For investors and consumers, paying close attention to market dynamics and arranging procurement plans reasonably are important strategies to cope with price fluctuations.

The technical requirements for hot-rolled strip steel mainly include four aspects

(1) High dimensional accuracy requirements. Dimensional accuracy mainly refers to thickness accuracy, because it not only affects the performance and the subsequent process of continuous automatic stamping, but also has the greatest control difficulty in production. In addition, thickness deviation has a great impact on metal saving.

(2) The plate shape should be good. The plate shape should be flat and free of waves and bends to be good for use. However, since plates and strips are both wide and thin, they are particularly sensitive to uneven deformation, so it is not easy to maintain a good plate shape. The thinner the plate or strip, the greater its sensitivity to uneven deformation, and the more difficult it is to maintain a good plate shape. Obviously, the poor plate shape comes from uneven deformation, and uneven deformation often leads to uneven thickness. Therefore, the quality of the plate shape is often directly related to the thickness accuracy.

(3) The surface quality should be good. Plates and strips are the steel with the largest surface area per unit volume, and are mostly used as peripheral components, so the surface quality must be guaranteed. Surface defects not only damage the appearance of plate parts, but also often deteriorate the performance or become the source of cracks and rust, and become a weak link for stress concentration.

(4) Good performance. The performance requirements of plates and strips mainly include mechanical properties, process properties and special physical or chemical properties of certain steel plates. General structural steel plates are only required to have good process properties, such as cold bending and welding properties, and the requirements for mechanical properties are not very strict.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.