Welcome!

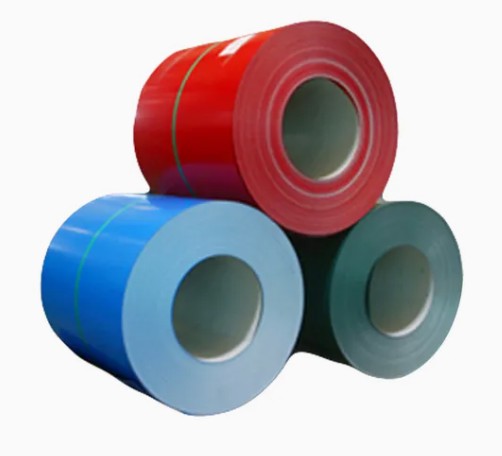

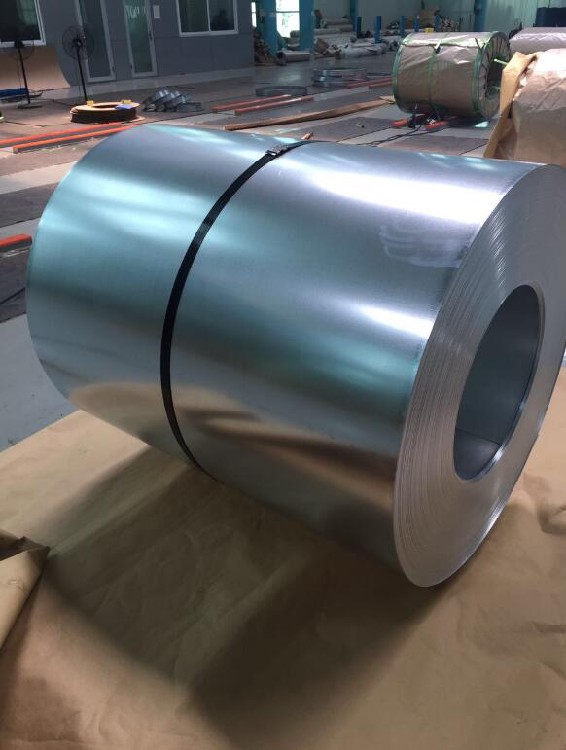

high strength hot rolled steel strip price

Product Description

looking back at the hot-rolled strip market price in August 2024, it continued to weaken, and the price hit a new low in recent years. Due to factors such as limited release of macroeconomic policies, deepening off-season effects, insufficient release of terminal demand, and cost resilience support, the domestic steel market has shown a fluctuating decline, causing steel mills to once again turn into a loss-making situation.

Looking forward to the hot-rolled strip market in September 2024, there are currently two major expectations. One is the expectation of the Federal Reserve's interest rate cut in September, and the other is that the traditional peak season of "Golden September and Silver October" is coming. This article briefly summarizes the market in August 2024 from the perspectives of price, cost, supply and demand, and makes a simple prediction of the price trend of hot-rolled strip in September 2024, as follows:

The price of hot-rolled strip fluctuated and weakened in August, and the profits of steel mills gradually decreased, but the degree of loss was acceptable. As of August 28, the theoretical calculated cost of long-process steel mills was 3,226 yuan/ton, and the gross profit was -66 yuan/ton; the theoretical calculated cost of strip steel mills was 3,290 yuan/ton, and the gross profit was -80 yuan/ton.

As of August 30, the operating rate of Mysteel's key hot-rolled strip steel producers in China was 53.7% this week, a weekly decrease of 3.71% and a monthly decrease of 12.97 percentage points. The capacity utilization rate was 58.4%, a weekly decrease of 4.94 percentage points and a monthly decrease of 13.29 percentage points. The actual output of steel mills this week was 1.729 million tons, a weekly decrease of 146,300 tons and a monthly decrease of 356,300 tons. The in-plant inventory of steel mills was 545,200 tons, a weekly decrease of 36,000 tons and a monthly decrease of 2,800 tons. The total inventory of China's major hot-rolled strip steel market samples this week was 828,700 tons, a decrease of 12,900 tons from last week, a decrease of 91,800 tons from the same period last month, and an increase of 340,000 tons from the same period last year.

Common quality problems and causes of hot-rolled strip production

(1) Crack problem

The surface cracks of hot-rolled strip mostly appear in the form of longitudinal cracks, with different depths and lengths. Various crack defects existing in the slab itself are the main cause of cracks in strip processing, and the cracks carried by the raw material billet cannot be eliminated in subsequent processes. In some cases, due to unscientific crystallizer and heat flow control, defects on the surface of the crystallizer copper plate, etc., the slab shell grows unevenly, and the stress imbalance causes cracks in the slab.

(2) Scar problem

The scar problem mainly affects the flatness of the strip product surface, and it is easy to become a weak stress link, causing the strip to break in the subsequent rolling process. Scars will be distributed on the strip surface in irregular strips, spots, etc., and severe ones will cause rough pitting on the strip surface. The scar problem is mainly caused by the pressure of iron oxide scale. The reasons can be found from the production process: First, the slab is heated for too long, and the iron oxide scale formed on its surface is large and thick. It is difficult to remove the iron oxide scale in the descaling process, resulting in it being pressed into the strip surface in the subsequent rolling process; second, the descaling water pressure is insufficient or the descaling process is unscientific, resulting in poor descaling effect; third, the roll tonnage is too high or the rolling force is set unreasonably, resulting in the strip surface being worn and causing roughness.

(3) Indentation problem.

The indentation defect on the strip surface is generally distributed periodically, with a relatively fixed length and width. The occurrence of indentation defects is mainly caused by roller surface damage, roller surface slag or rolled piece falling off. The indentation problem seriously affects the flatness of the hot-rolled strip surface.

(4) Surface bulge

The problem of strip surface bulge generally occurs at the edge of the strip, and is distributed in a strip-like shape along the rolling direction of the strip. The cause of the bulge defect on the edge of the hot-rolled strip is mainly due to local wear of the working roll.

Common quality problems and solutions for hot-rolled strip

(1) Solutions to crack problems

First of all, we should pay attention to the maintenance of the equipment in the continuous casting process to avoid the peeling of the coating during the use of the equipment; we should also pay attention to improving the protective slag system. By summarizing the production experience of different steel grades, we can formulate the flow field area and taper table of the crystallizer suitable for different steel grades and specifications to improve the production quality of hot-rolled strip.

(2) Solutions to the streak problem

The main approach should be to prevent the intrusion of iron oxide scale. First of all, we should reasonably formulate heating measures to avoid excessive iron oxide scale generation due to too long heating time and too high heating temperature; then we should ensure the descaling effect, and ensure the descaling water pressure by adjusting the descaling water pressure and cleaning the nozzle blockage. At the same time, we should also reasonably adjust the rolling force and tonnage of the roll to avoid wear on the strip surface.

(3) Solutions to the indentation problem

To solve the indentation problem of hot-rolled strip, we should first check whether the roll surface is worn or sticky. If the wear is minor, the roller surface can be repaired and ground. If the indentation is severe, the roller must be replaced immediately.

(4) Solutions to the bulge problem

Optimize the roller convexity and improve the roller grinding accuracy. Also, avoid problems such as poor water cooling and uneven roller wear caused by nozzle blockage. For rollers with severe wear, repair and replace them in time.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.