Welcome!

Stainless Steel Tube: A Premium Solution for Diverse Applications

Basic Info

| Certs | ISO 9001-2008, Ce. PED,Ts | Delivery Time | 20-30days | End | PE/Be |

|---|---|---|---|---|---|

| Length | 5m-12m | Material | Stainless Steel | Model NO. | 304l |

| Origin | China | Production Capacity | 2000ton/Month | Section Shape | Round |

| Specification | as Demand | Surface Treatment | Varinished,Polished,Antiseptical,Oiled, | Transport Package | Nuded Cargo or Nylon Bags or Wooden Box |

| Usage | Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products, Mining, Construction & Decoration | Wall Thickness | 0.5mm-60mm | ||

Product Description

Product Overview

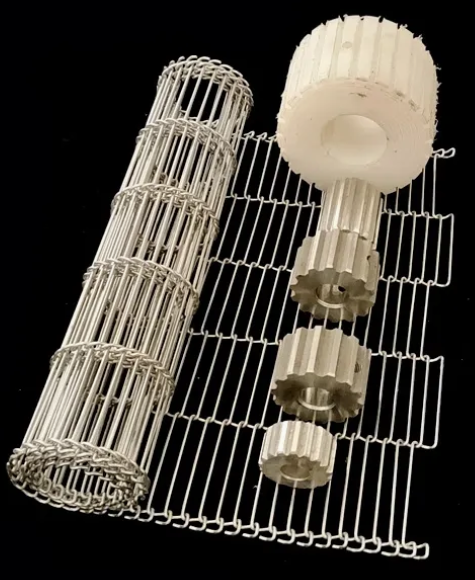

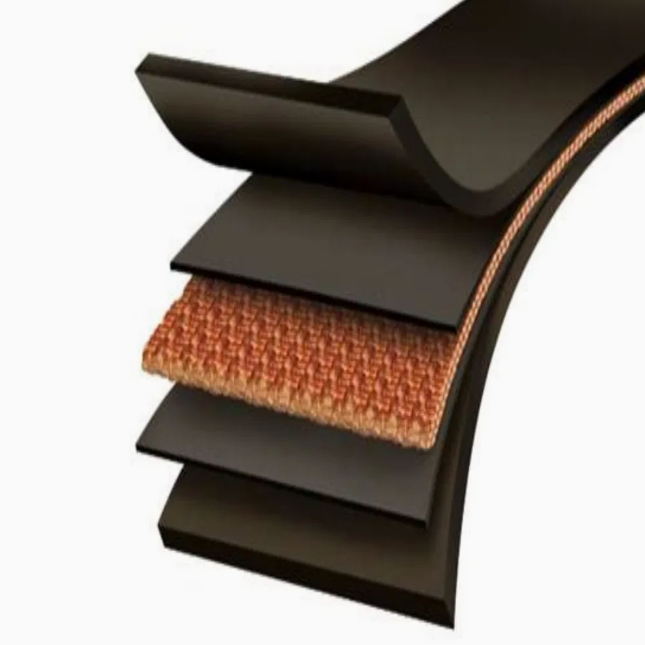

Stainless steel tubes are high-performance cylindrical components crafted from corrosion-resistant stainless steel alloys, renowned for their durability, versatility, and adaptability to demanding environments. These tubes are manufactured through advanced welding or seamless forming techniques, ensuring precision in dimensions and consistency in quality. Available in a wide range of sizes, thicknesses, and surface finishes (e.g., polished, brushed, or matte), stainless steel tubes meet the rigorous requirements of industries such as construction, automotive, chemical processing, medical equipment, food and beverage, and energy.

The material composition typically includes chromium, nickel, and molybdenum, which enhances resistance to oxidation, extreme temperatures, and corrosive substances. Common grades include 304/304L (general-purpose), 316/316L (marine/chemical resistance), and 321 (high-temperature stability), ensuring suitability for specialized applications.

Key Advantages of Stainless Steel Tubes

1. Superior Corrosion Resistance

Stainless steel tubes excel in harsh environments, resisting rust, acids, alkalis, and chloride exposure. This makes them ideal for marine settings, chemical plants, and outdoor installations.

2. Long-Term Durability

With high tensile strength and impact resistance, these tubes maintain structural integrity under pressure, vibration, and temperature fluctuations, reducing replacement costs over time.

3. Hygienic & Easy to Clean

The non-porous surface prevents bacterial growth, meeting strict hygiene standards for food processing, pharmaceuticals, and medical devices. Smooth finishes allow effortless sterilization.

4. Aesthetic Appeal

Stainless steel’s sleek and modern appearance complements architectural designs, decorative structures, and consumer products without requiring coatings or paints.

5. Environmental Sustainability

Fully recyclable and made from eco-friendly materials, stainless steel tubes support green initiatives and circular economy practices.

6. Lightweight Yet Robust

Compared to traditional materials like carbon steel, stainless steel tubes offer comparable strength with reduced weight, optimizing efficiency in transportation and assembly.

7. Thermal & Electrical Conductivity

Suitable for heat exchangers, exhaust systems, and electrical conduits, these tubes ensure efficient energy transfer while maintaining stability.

8. Customization Flexibility

Tailored solutions are achievable through adjustable diameters, wall thicknesses, lengths, and shapes (round, square, rectangular), catering to unique project specifications.

9. Cost-Effective Lifecycle

Low maintenance needs and extended service life minimize downtime and operational expenses, delivering long-term value.

Applications

Stainless steel tubes are widely utilized in:

1. Construction: Handrails, structural frameworks, HVAC systems.

2. Automotive: Exhaust systems, fuel lines, hydraulic components.

3. Industrial: Pipelines, machinery parts, heat exchangers.

4. Medical: Surgical instruments, diagnostic equipment.

5. Food & Beverage: Processing machinery, sanitary fluid transport.

Why Choose Us?

QingzhouJianfu Gear Co., Ltd. is a leading manufacturer specializing in the design, production, and distribution of high-precision gears and transmission components, serving diverse industries including automotive, machinery, agricultural equipment, and industrial automation. Established with a commitment to innovation and quality, the company leverages advanced manufacturing technologies, rigorous quality control systems, and a skilled engineering team to deliver durable and customized solutions tailored to global clients' needs. With a focus on reliability, efficiency, and cost-effectiveness, QingzhouJianfu Gear has built a reputation for excellence in both standard and bespoke gear production, ensuring seamless integration into complex mechanical systems while adhering to international standards. Its customer-centric approach emphasizes collaborative partnerships, timely delivery, and continuous technical support, solidifying its position as a trusted partner in the global supply chain.

Conclusion

Stainless steel tubes represent a smart investment for industries prioritizing reliability, safety, and efficiency. Their unmatched combination of strength, corrosion resistance, and adaptability ensures optimal performance across countless applications. For technical specifications or project-specific guidance, consult with a trusted supplier to identify the ideal grade and configuration for your needs.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.