Welcome!

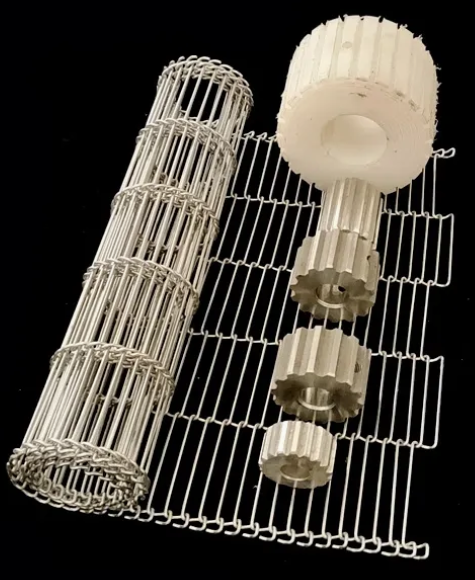

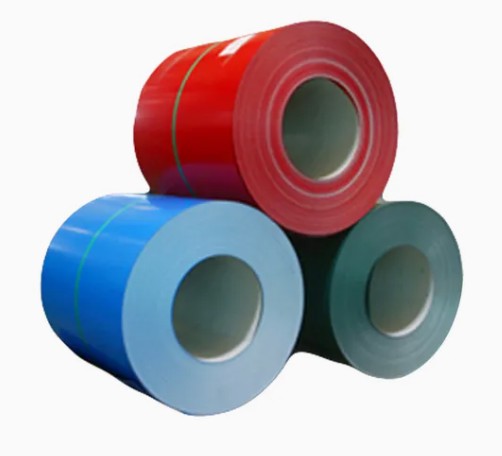

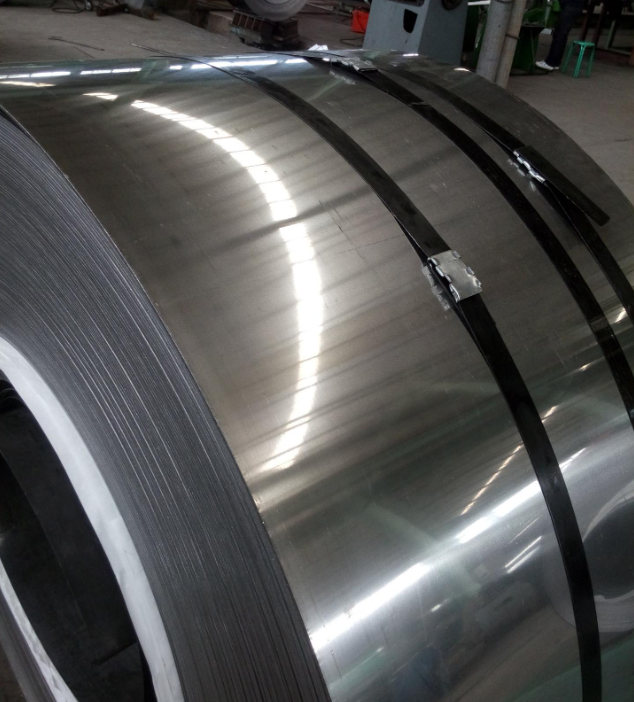

Cold Rolled Stainless Steel Strip Suppliers

Product Description

Cold-rolled stainless steel strip production technology

1. Types of cold rolling mills

Rolling stainless steel, a high alloy, high hardness material with a high tendency to harden during cold rolling, requires high efficiency and high precision, so a high-rigidity rolling mill must be used.

Initially, stainless steel cold rolling mostly used a four-roll reversible rolling mill. Although the working rolls and support rolls of the four-roll rolling mill have large diameters and a large arch, the rolling mill is not rigid enough and the rolling accuracy is not high. In response to this situation, multi-roll rolling mills such as the MKW eight-roll rolling mill, twelve-roll rolling mill, and twenty-roll rolling mill have been gradually developed.

Compared with four-roll mills, multi-roll mills have the following advantages:

(1) In multi-roll mills with tower-shaped support rolls (12-roll and 20-roll mills), the entire roll body of the working roll is supported on the mill arch by the saddle of the support roll. The bending deformation in the width direction of the roll is very small, so that small-diameter working rolls can be used;

(2) Since the rigidity of the mill is improved and high-hardness rolls are used, and the working rolls can be quickly replaced, it is possible to produce high-precision and high-quality surface steel strips;

(3) It provides the possibility of producing wide and thin steel strips with a thickness of 0.5-0.05mm;

(4) Strengthening reduction is implemented on multi-roll mills, which reduces the number of mill passes and may reduce the rolling stroke, thereby improving production efficiency and reducing costs;

(5) The mill is small in size and light in weight, which relatively reduces equipment costs.

2. Factors affecting cold rolling

A: Friction coefficient (rolling lubricant)

Stainless steel cold rolling mills must use rolling lubricants, especially when rolling on multi-roll mills (12-roller and 20-roller mills). There are two purposes: one is process lubrication, reducing the friction coefficient on the contact surface between the roll and the steel strip, reducing the rolling pressure and the required transmission power, and improving the surface condition of the product; the other is to cool the roll and the steel strip, remove the deformation heat generated during the rolling process, and keep the mill in normal working condition.

The lubricants used in multi-roll mills include mineral oil and emulsion. The friction coefficient between the roll and the steel strip varies depending on the type of lubricant and the lubrication method. It is related to the surface condition of the roll and the steel strip, as well as the rolling temperature, rolling speed, reduction rate and other conditions, and is usually between 0.04 and 0.15.

B: Front and rear tension

The tension during cold rolling has a great influence on the rolling pressure, and is also an important factor affecting the plate shape and thickness. Multi-roll mills use high tension rolling, and the cold rolling of stainless steel strips requires a higher tension. On a single-stand reversible rolling mill, tension is generated between the rolling mill and the coiler; the coiler that forms the front tension is in an electric working state, while the coiler that forms the rear tension is in a power generation working state. During the rolling process, constant tension control is generally used to maintain the tension unchanged. As the diameter of the coil of the front coiler becomes larger and larger, the coiler should gradually slow down; while the diameter of the coil of the rear coiler becomes smaller and smaller, it should be gradually accelerated to keep the corresponding line speed unchanged.

Different front and rear tensions are set for different rolling mills, different materials and different product specifications. The maximum unit tension value is generally within the range of (0.3-0.5). The tension of the Ni-Cr stainless steel strip rolled by the twenty-roll Sendzimir rolling mill is 390~490MPa; the tension of the chromium stainless steel strip rolled is 295-390MPa. Generally, in the first rolling, because the coiling tension of the pickling unit is small, a large tension cannot be used to avoid the interlayer displacement of the coil and scratching the surface. In the subsequent passes, high tension rolling can be applied. Depending on the type and specification of the rolled product, the front tension may be greater than the rear tension, or the rear tension may be greater than the front tension. When rolling ferritic stainless steel strips and annealing in a bell furnace after rolling, the unit tension of the finished product pass should be appropriately reduced to prevent adhesion during annealing. The tension should also be appropriately reduced when the weld passes the rollers.

C: Rolling speed

The change of rolling speed will affect the friction coefficient between the roll and the steel strip, thus affecting the rolling pressure and the thickness of the steel strip. The rolling speed of the multi-roll mill is high. The rolling speed of the modern twenty-roll mill for rolling stainless steel strip can reach 800m/min (the bandwidth is not less than 1110mm) and 1000m/min (the bandwidth is 1320mm).

High rolling speed requires the hot-rolled strip to have completely good performance, because certain defects on the material will have more impact at high speed rolling than at lower rolling speed, resulting in greater damage to the rolling equipment and products. Therefore, a lower rolling speed is used when arranging the first rolling pass, so as to accurately inspect the rolled steel strip and record the location of defects that affect high-speed rolling. Starting from the second pass, the rolling speed is increased and the speed is reduced to pass the defective part under the conditions of utilizing the mill motor capacity and strip tension.

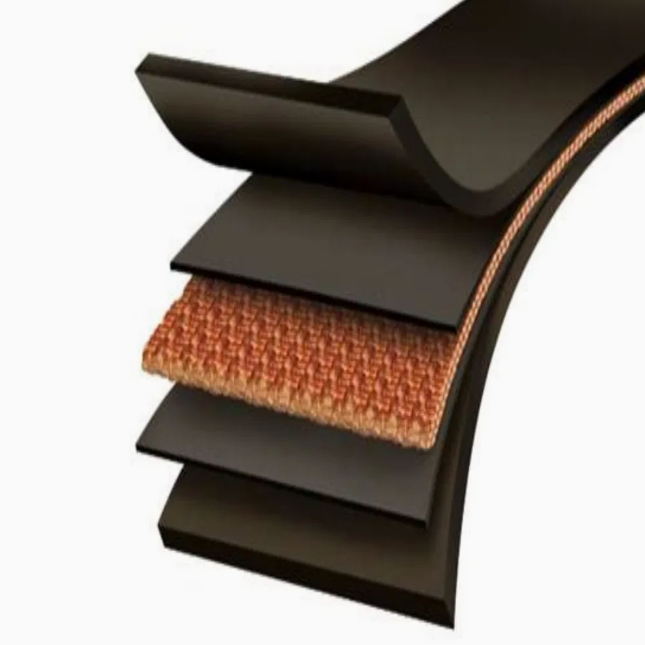

D: Roller

The roller used in the cold rolling mill must have high hardness, strength and wear resistance, and must also have a certain toughness. The rolls used in the multi-roll cold rolling mill are made of high-chromium steel and high-speed steel. Rollers in different parts should be made of steel with different compositions. In order to ensure the surface quality of cold-rolled products, strict requirements are imposed on the surface of the working rolls. Not only must the surface have a certain degree of roughness, but there must not be any visible defects (cracks, pits, indentations, grinding patterns, spiral patterns, etc.). The rolls must be carefully ground and inspected before use. During the rolling process, frequent inspections must be carried out, and rolls must be replaced immediately if problems are found. Therefore, when rolling stainless steel strips, roll changes are very frequent. Generally, the working rolls must be replaced once for each roll, and sometimes several times.

3. Pressing system

The pressing system includes the regulations on rolling passes, pressing amount and rolling process. The pressing system should be determined according to the characteristics of the rolling mill (rolling mill model, main motor power, rolling pressure, roll hardness, process lubrication, coiling motor power and tension, etc.), and change with the type, size and heat treatment quality of the rolled products. A reasonable pressing system is of great significance to improving rolling efficiency, product quality and reducing consumption. In fact, when formulating the pressing plan; the pressing system is determined according to the pressure of the metal on the roll and the load of the main motor. Usually in the first two passes, the pressing amount is limited by the load of the main motor. In cold rolling, a large pressing amount is often specified in the first pass, and the pressing amount is gradually reduced in the subsequent passes so that the pressure of the metal on the roll is consistent in each pass.

In some cases, in order to produce work-hardened steel strips or steel strips with minimal warpage and uniform thickness, the rolling passes are significantly increased. During rolling, the unit pressure and total pressure of the metal on the roll shall not exceed the design standard. For a four-roll mill, the unit pressure is no more than 1700MPa; for a multi-roll mill, the unit pressure is in the range of 2000-2500MPa. The reduction of each pass and the total reduction of a rolling process also depend on the mechanical properties of the rolled steel strip and its changes during the rolling process. For example, after quenching, a 1Crl8Ni9Ti stainless steel strip with a pressure of =320MPa and a pressure of =50% is rolled from 3mm to 1.5mm on a 1680mm four-roll reversible cold rolling mill in 7 passes; while a 1Crl8Ni9Ti stainless steel strip with a pressure of =600MPa and a pressure of =26% is rolled from 3mm to 1.5mm under the same conditions. It takes 9-11 passes to complete the rolling process. Process lubrication and roll surface roughness have a great influence on the reduction system. For example, 1Crl8Ni9Ti stainless steel strip, on a 1680mm four-roller reversible rolling mill, uses No. 20 machine oil as a process lubricant, and uses rollers with a surface roughness of Ra=0.8 or Ra=0.4 to roll the thickness from 3mm to 1.5mm in 11 passes. However, if a roller with a surface roughness of Ra=0.1 is used to roll the same specification product, the number of rolling passes may be reduced to 9 or even 7.

By using effective process lubrication, it is possible to increase the total reduction rate of one rolling process to 80% or higher. According to the traditional process, when using No. 20 engine oil, it takes two rolling processes (intermediate heat treatment when the strip thickness is 1.5mm) to roll a 3mm thick billet to a 0.7mm thick finished product, with a total of 16 passes, and a total reduction rate of 50% and 53.3% between the two heat treatments. When using a bright oil called 28, it can be rolled in one rolling process with a total reduction rate of 76.7% under the condition that the number of passes can be reduced to 11. When using polymer cottonseed oil, a large coil billet with a thickness of 3.8mm can be rolled into a 0.7mm thick finished product with a total reduction rate of 81.6% in 13 passes. With such a reduction, not only austenitic stainless steel with good plasticity can be rolled, but also austenitic-ferrite and austenitic-martensitic stainless steel that are difficult to deform can be rolled. The forced reduction system will increase the temperature of the steel strip, thereby improving the plasticity of the steel strip. Under this condition, although the total reduction is quite large, the steel strip will not crack during rolling.

Implementing enhanced reduction on a multi-roll mill can reduce the number of rolling passes and the number of intermediate annealing.

Stainless steel uses a four-roll mill to roll a 0.4-0.5mm thick finished product from a 3.0mm thick billet, which requires an intermediate heat treatment. However, when rolling with a multi-roll mill, no intermediate heat treatment is required. Stainless steel strips with high-quality surfaces can be produced without intermediate heat treatment and with a large reduction. Under the condition of a total reduction rate of 97%, the high strength and high rigidity of the multi-roll mill make it possible to keep the relative reduction of each pass unchanged, so that the power of the main motor can be used more effectively than other types of rolling mills.

4. Shape control

The purpose of shape control is to roll out strips with uniform transverse thickness and straight appearance. In shape control, the transverse thickness difference of the steel strip and the straightness of the steel strip are two different physical concepts. The transverse thickness difference is an indicator of the uneven thickness distribution on the cross section of the steel strip; the straightness is an indicator that the steel strip loses its flat surface characteristics and has shape defects such as wavy and warping. The direct cause is the uneven deformation of the rolled steel strip in the width direction. There is no necessary connection between the two. The transverse thickness difference of the rolled steel strip is very small, but its straightness may be very poor due to uneven deformation. However, the two are also very closely related, and they both depend on the shape of the working roll roll curve during rolling.

Therefore, shape control is to adjust the shape of the loaded roll gap under the condition that the incoming material shape is good, so that it is consistent with the cross-sectional shape of the incoming steel strip, so as to reduce the transverse uneven deformation and make the rolled plate shape straight. Adjusting the shape of the loaded roll gap is relatively easy for various forms of twenty-high rolling mills. Due to the structural characteristics of the twenty-high mill, there are a variety of plate shape adjustment methods, generally with radial roll shape adjustment mechanism, axial roll shape adjustment mechanism; split mill has roll tilt adjustment function; some direct-pressed twenty-high mills are also equipped with hydraulic roll bending mechanism, etc. For the four-high mill, the most basic method of plate shape control is to determine the appropriate roll convexity, that is, considering the pressure distribution characteristics in the width direction of the steel strip, the roll is ground into a slightly convex shape in the middle part. Modern four-high mills also use other plate shape adjustment mechanisms, such as roll tilting, hydraulic roll bending, CVC mill roll axial movement, emulsion flow segment control, etc. In addition, the quality of plate shape is also affected by some other operating factors, such as the appropriateness of tension and rolling pressure. Generally, the quality of plate shape is reflected by the tension of each part along the width direction of the steel strip during rolling, which requires the operator's experience to judge and adjust. In recent years, online detection devices and various control technologies for plate shape have been more and more widely used in production, especially in wide steel strip mills, and will become an important development direction of cold rolling technology in the future.

5. Thickness control

Cold-rolled stainless steel strips should have uniform thickness and small deviation, which is an important indicator for measuring product quality. Controlling the thickness of steel strips depends largely on improving the rolling accuracy of cold rolling. It is necessary to try to reduce and eliminate uneven thickness and minimize the thickness deviation range.

Uneven thickness of steel strips is caused by two reasons: one is poor cold rolling raw materials, such as uneven thickness of hot-rolled coils and poor annealing of billets, which leads to uneven deformation resistance in the length direction of the steel strip; the other is caused by cold rolling itself, such as tension changes, speed changes, roll eccentricity, and changes in the oil film thickness of roll bearings. For the former, in addition to requiring improvements in the previous process, efforts should be made to eliminate it during cold rolling. For the latter, it depends on continuous improvement of cold rolling operations.

With the continuous improvement of cold rolling mill speed and stainless steel product quality, manual thickness adjustment can no longer meet the requirements, so stainless steel cold rolling mills are equipped with automatic thickness control devices (AGC-). AGC is a method of continuously measuring the actual thickness of the steel strip through a thickness gauge or sensor, and obtaining a deviation signal based on the comparison between the measured value and the given value. With the help of detection control loops and devices or computer function programs, the pressing position, tension or rolling speed is changed to control the thickness within the allowable deviation range.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.