Welcome!

Stainless Steel Belts: Innovation Meets Industrial Reliability

Basic Info

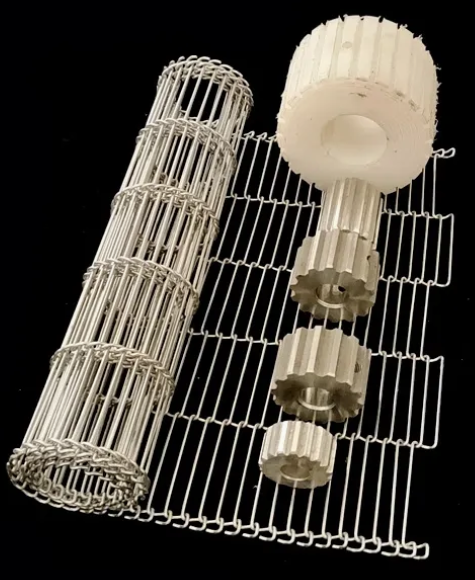

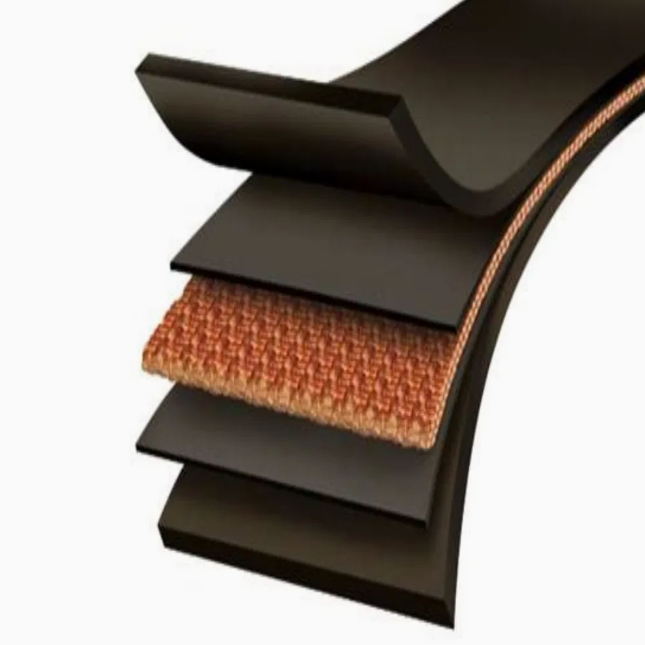

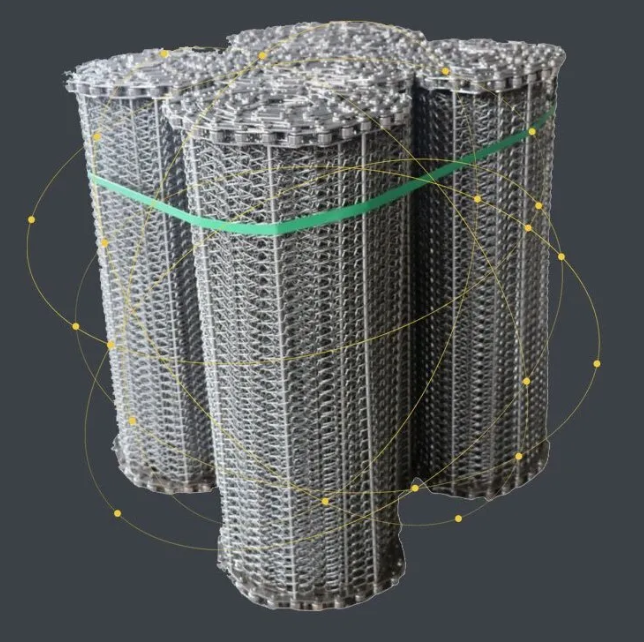

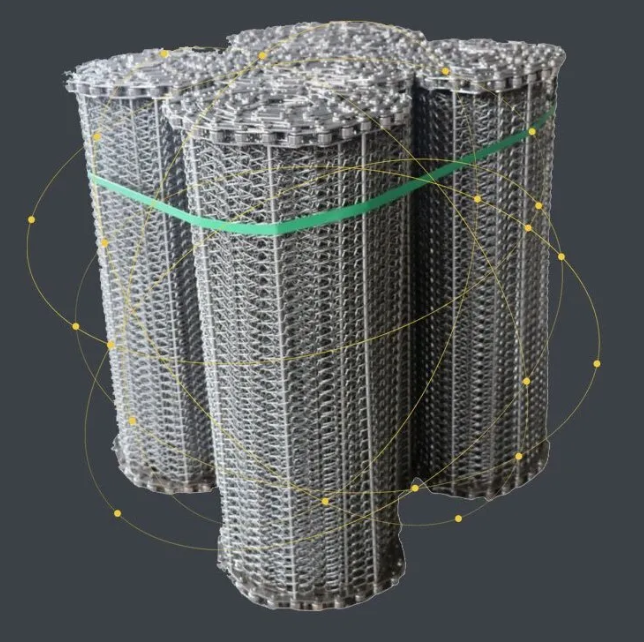

| Compound Balance Belt | Wire Mesh | Feature | Oil-Resistant, Heat-Resistant, Cold-Resistant | Inside Material | Stainelss Steel |

|---|---|---|---|---|---|

| Mesh Belt | Conveyor Wire Mesh | Model NO. | m001 | Origin | China |

| Production Capacity | 55m Each Day | Specification | A410.5-5.7-2.6-2.3, A3-4.4-3.5-1.8-1.2 | Stainless Steel Conveyor Belt | Metal Mesh Belt |

| Tensile Strength | Strong | Transport Package | Standard Wooden | Wire Mesh Belt | Wire Mesh |

Product Description

Product Overview

Stainless steel belts are advanced engineering solutions crafted to address the evolving challenges of modern manufacturing and processing industries. Utilizing premium stainless steel alloys, these belts are precision-manufactured through state-of-the-art processes such as cold forging, precision annealing, and surface finishing. Designed for versatility, they are available in customizable widths, thicknesses, and tensile strengths to integrate seamlessly into applications ranging from automated production lines to precision-driven laboratory equipment.

Their inherently smooth and non-reactive surface ensures contamination-free operation, while optional modifications such as micro-perforations, embossed patterns, or anti-static coatings expand their utility in specialized sectors like semiconductor fabrication, renewable energy systems, or high-precision printing. Engineered for seamless integration, these belts deliver consistent performance in both static and dynamic load environments, ensuring reliability across industries.

Competitive Advantages

1. Superior Material Science

Constructed from corrosion-resistant alloys (e.g., 304L, 316Ti, or duplex grades), these belts withstand aggressive chemicals, saltwater, and extreme thermal cycles, making them ideal for marine, chemical, or oil and gas applications.

2. Optimized for Precision

Ultra-flat surfaces and tight dimensional tolerances (±0.01mm) ensure flawless performance in applications requiring micron-level accuracy such as optical lens polishing, battery electrode coating, or microelectronics assembly.

3. Extended Service Life

Enhanced fatigue resistance and anti-galling properties reduce wear even under high-frequency cycling, significantly extending operational lifespan compared to conventional belts.

4. Hygiene and Compliance

Electropolished finishes and crevice-free designs meet stringent hygiene standards (e.g., EHEDG, 3-A), making them indispensable for food-grade production, biopharmaceuticals, and sterile packaging.

5. Energy Efficiency

Low-friction surfaces and lightweight designs minimize power consumption in conveyor systems, aligning with sustainability goals while boosting operational cost-efficiency.

6. Rapid Customization

Tailored solutions, including pre-drilled holes, edge reinforcements, or heat-resistant coatings, can be rapidly prototyped and deployed to meet urgent production demands.

7. Global Certification

Compliant with ISO 9001, RoHS, and REACH standards, these belts ensure quality and safety for global supply chains, reducing compliance risks for multinational operations.

Why Choose Us?

Qingzhou Jianfu Gear Co., Ltd. is a leading manufacturer specializing in precision gears and transmission components, dedicated to delivering robust solutions across diverse industries such as automotive, machinery, agricultural equipment, industrial automation, and renewable energy. With years of expertise, the company combines advanced manufacturing technologies, state-of-the-art equipment, and rigorous quality management to ensure high-performance and durable products tailored to global client needs. Committed to innovation and sustainability, Qingzhou Jianfu Gear emphasizes customer collaboration, offering customized designs, competitive pricing, and efficient service. As an ISO-certified enterprise, it adheres to international standards while fostering long-term partnerships through reliability, flexibility, and continuous improvement in every project.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.