Welcome!

corrosion resistant steel strip wholesale price

Product Description

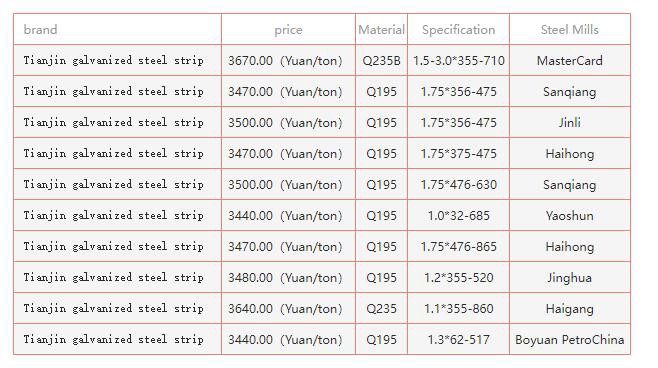

The latest price of galvanized steel strip on September 18, 2024

Corrosion-resistant steel strip is a kind of steel with excellent corrosion resistance, suitable for various highly corrosive environments. This kind of steel strip usually has alloy elements such as high nickel, high chromium, and high molybdenum to improve its corrosion resistance and high temperature resistance.

Common types of corrosion-resistant steel strips

904L stainless steel strip: It belongs to austenitic stainless steel, with the characteristics of low carbon, high nickel and molybdenum, and is a proprietary material introduced from the French H·S company. It has good activation-passivation transformation ability and good corrosion resistance, especially suitable for non-oxidizing acid and neutral chloride ion medium, with good resistance to pitting, crevice corrosion and stress corrosion.

NS3304 steel strip: This is a super austenitic stainless steel containing a high proportion of chromium, nickel and molybdenum, with extremely high corrosion resistance and processing performance. It is famous for its excellent resistance to pitting, stress corrosion and chloride ion corrosion, and is suitable for various highly corrosive environments.

X1NiCrMoCu25-20-5 steel strip: It is a super austenitic stainless steel, which also has the characteristics of low carbon, high nickel and molybdenum, and has good activation-passivation transformation ability and corrosion resistance. It is suitable for non-oxidizing acids and neutral chloride ion media, and has good resistance to pitting corrosion, crevice corrosion and stress corrosion. 304 stainless steel strip: Although it is not a specially designed corrosion-resistant steel strip, 304 stainless steel also has a certain corrosion resistance and can resist corrosion from most industrial and organic acids, as well as alkalis, salts and other chemical substances. It has good corrosion resistance, heat resistance, low temperature strength and mechanical properties, and is suitable for a variety of uses

The process flow of corrosion-resistant steel strip mainly includes raw material selection, raw material acceptance, raw material storage, raw material preparation, heating and rolling.

Raw material selection: According to product specifications and quality requirements, select suitable stainless steel raw materials to ensure that the chemical composition, mechanical properties and surface quality meet the standards. Raw material acceptance: Conduct quality inspection on raw materials to ensure that the raw materials are free of defects, rust and impurities and meet production requirements. Raw material storage: Establish a good raw material storage environment, keep it dry and clean, and prevent raw materials from rusting and contamination. Raw material preparation: Heat the raw materials to the rolling temperature to ensure the smooth progress of the rolling process, while improving the rolling efficiency and product quality. Heating and rolling: Through multiple rolling passes, the heated raw materials are rolled into stainless steel strips to control the thickness, width and surface quality. According to the type of stainless steel and the characteristics of the rolling equipment, the rolling temperature and speed are reasonably controlled to ensure product performance and surface quality.

Application Range

These corrosion-resistant steel strips are widely used in industries such as chemical industry, marine engineering, paper industry, food processing, energy, etc. due to their excellent corrosion resistance and processing properties, especially in the treatment of corrosive chemicals or high temperature and high pressure environments. Their high corrosion resistance and good processing properties make these materials the first choice for many industrial applications.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.