Welcome!

Stainless Steel Belts: Versatile Engineering Solutions for Modern Industry

Basic Info

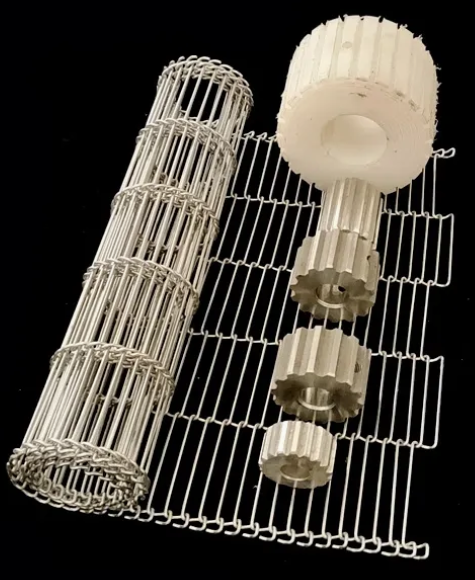

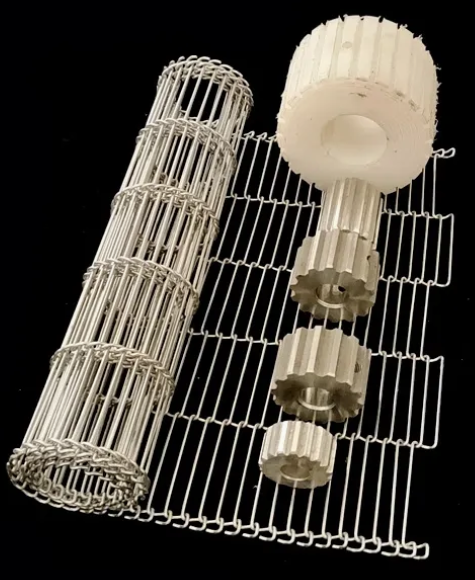

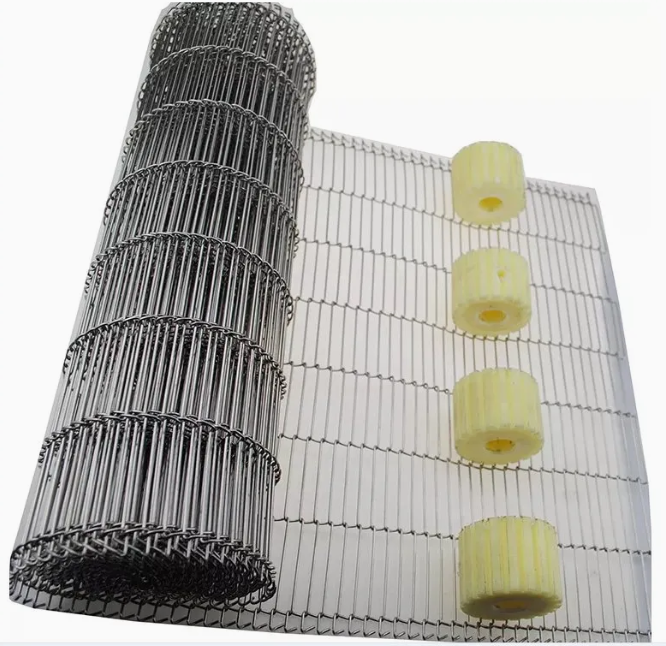

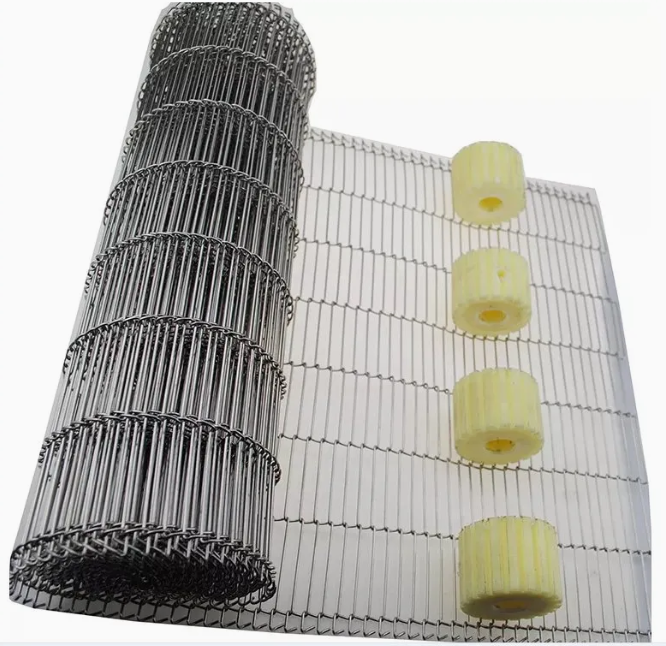

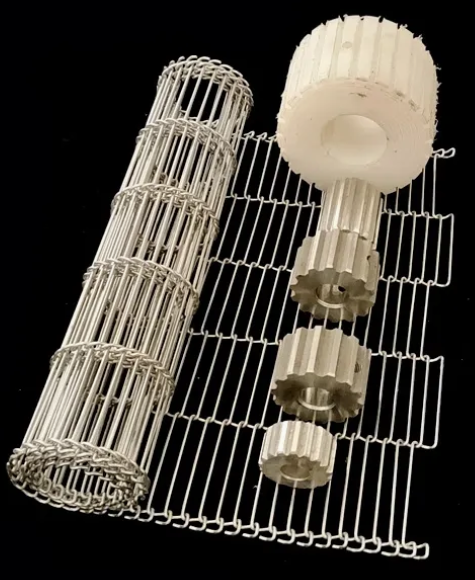

| Feature | Food Processing | Food Mesh | Wire Mesh | Inside Material | Stainless Steel |

|---|---|---|---|---|---|

| Ladder Belt | Mesh Belt | Model NO. | c001 | Origin | China |

| Production Capacity | 100m /Day | Specification | pitch from 4.0-22mm | Tensile Strength | Strong |

| Transport Package | Standard Wooden | Wire Mesh Belt | Wire Belt | ||

Product Description

Product Overview

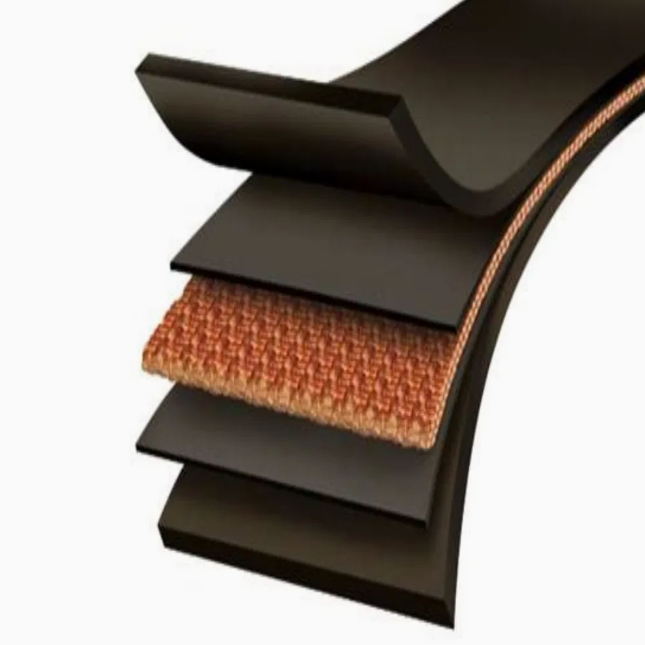

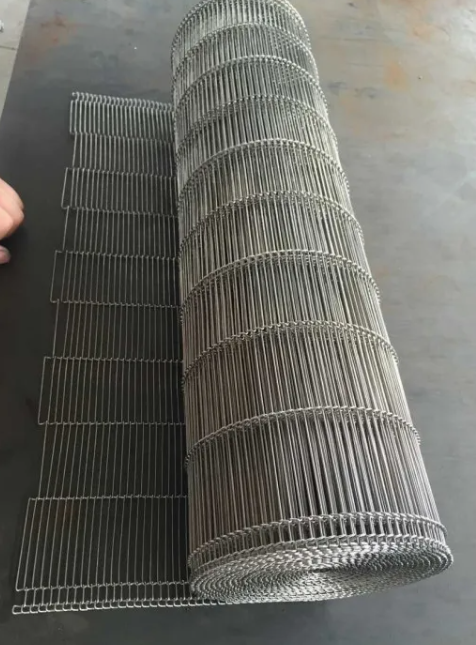

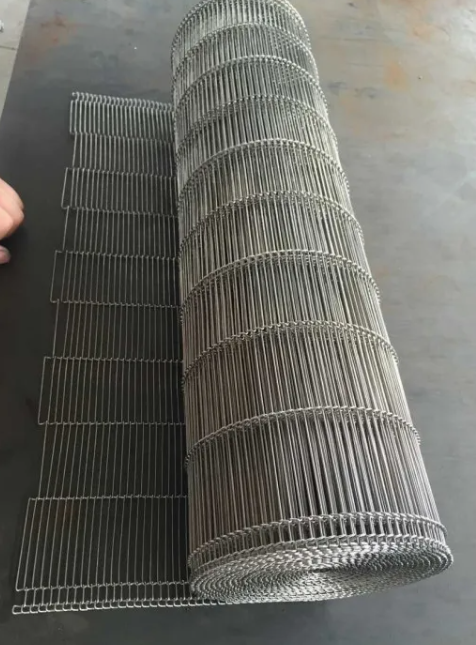

Stainless steel belts are precision-engineered components designed to deliver unmatched performance in demanding industrial and commercial applications. Manufactured using high-quality stainless steel alloys, these belts combine cutting-edge metallurgical techniques with rigorous quality control to ensure consistency, durability, and adaptability. Available in a wide range of configurations from ultra-thin and flexible designs to heavy-duty and load-bearing variants, they serve as critical components in industries such as logistics, packaging, automotive, energy, and textile manufacturing.

The belts’ seamless construction and polished surfaces minimize friction and wear, enabling smooth operation in high-speed machinery. Customizable features, including edge reinforcements, perforations, or specialized coatings, allow them to address unique operational challenges such as heat dissipation, product alignment, or static control. Their resistance to deformation under stress ensures precise tracking and alignment even in continuous-use environments.

Core Benefits

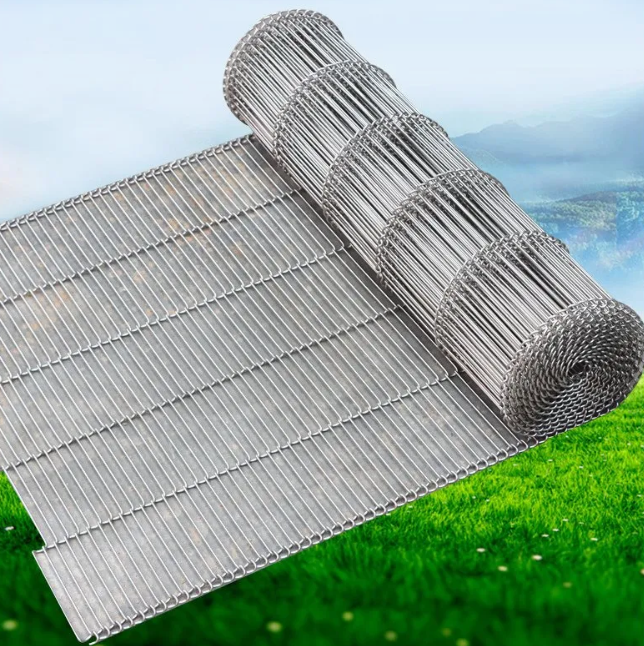

1. Adaptability to Extreme Environments

Stainless steel belts thrive in settings exposed to moisture, acids, alkalis, or extreme temperature fluctuations. Their resistance to thermal expansion and contraction guarantees stable performance in applications like freeze-drying processes, high-temperature curing, or chemical processing.

2. Enhanced Operational Efficiency

Engineered for low friction and high-speed operation, these belts reduce energy consumption and minimize wear on connected machinery. Their lightweight yet robust design supports faster production cycles without compromising accuracy.

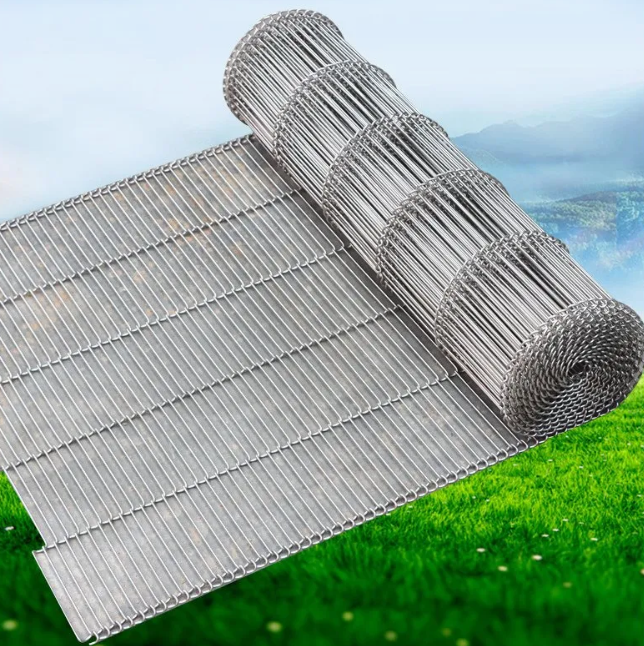

3. Long-Term Cost Savings

With exceptional resistance to abrasion, pitting, and surface degradation, stainless steel belts outlast traditional materials like rubber or plastic. This translates to fewer replacements, reduced maintenance, and lower total ownership costs.

4. Precision and Consistency

Tight tolerances and uniform thickness ensure reliable performance in precision-driven tasks such as laser cutting, printing, or electronic component assembly. The belts’ flat and stable surface guarantees consistent product handling and positioning.

5. Compliance with Industry Standards

Stainless steel belts meet stringent global standards for food safety (FDA, USDA), chemical resistance (ISO), and fire safety (UL), making them suitable for regulated industries like pharmaceuticals, aerospace, and clean energy.

6. Eco-Conscious Manufacturing

Produced with minimal waste and fully recyclable at end-of-life, these belts align with circular economy principles, supporting environmentally responsible production practices.

Who We Are?

Qingzhou Jianfu Gear Co., Ltd. is a leading manufacturer specializing in precision gears and transmission components, dedicated to delivering robust solutions across diverse industries such as automotive, machinery, agricultural equipment, industrial automation, and renewable energy. With years of expertise, the company combines advanced manufacturing technologies, state-of-the-art equipment, and rigorous quality management to ensure high-performance and durable products tailored to global client needs. Committed to innovation and sustainability, Qingzhou Jianfu Gear emphasizes customer collaboration, offering customized designs, competitive pricing, and efficient service. As an ISO-certified enterprise, it adheres to international standards while fostering long-term partnerships through reliability, flexibility, and continuous improvement in every project.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.