Welcome!

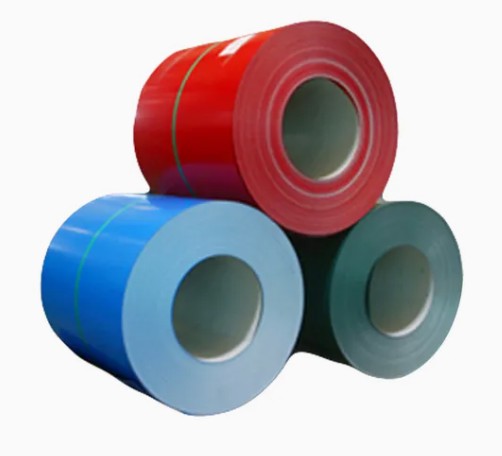

Cold Rolled Galvanized Steel Coil: Unmatched Durability Meets Precision Performance

Basic Info

| Application | Container Plate | Certification | ISO | Coated Zinc | 30-120g |

|---|---|---|---|---|---|

| Color | as Customers' request | Length | Coil | Model NO. | PPGI |

| Origin | China | Production | Capacity | Special Use | Decorating Materials |

| Specification | as Customers' request | Stock | Stock | Surface Treatment | Coated |

| Technique | Cold Rolled | Thickness | 0.1-2.0mm | ||

Product Description

Description

Cold Rolled Galvanized Steel Coil is a premium-grade steel product engineered for durability, versatility, and superior performance. Manufactured through a precise cold-rolling process, and followed by a hot-dip galvanization treatment, this steel coil combines the strength of cold-rolled steel with the corrosion resistance of a zinc coating.

The product features a smooth and uniform surface finish, making it ideal for applications requiring both aesthetic appeal and structural integrity. Available in a range of thicknesses (0.2mm to 3.0mm), widths (600mm to 1500mm), and coil weights (3 to 15 tons), it caters to diverse industrial and commercial needs. The zinc coating, typically ranging from 60g/m² to 275g/m², ensures long-term protection against rust and environmental wear.

Designed for industries such as construction, automotive manufacturing, home appliances, and solar energy systems, cold rolled galvanized steel coils are also customizable with additional treatments (e.g. passivation, oiling, or chromating) to meet specific project requirements.

Key Advantages

1. Exceptional Corrosion Resistance

Zinc coating acts as a sacrificial layer, shielding the base steel from moisture, chemicals, and harsh weather conditions. This extends the product’s lifespan significantly, even in coastal or high-humidity environment.

2. High Strength & Formability

The cold-rolling process enhances the steel’s mechanical properties, delivering excellent tensile strength and flexibility. It can be easily shaped, welded, or punched without compromising structural stability, which is perfect for intricate designs.

3. Superior Surface Quality

With a flawless and spangle-free finish, the steel coil is ready for painting, powder coating, or direct use in visible applications. Its consistent texture ensures optimal adhesion for coatings and reduces post-processing costs.

4. Cost-Effective & Sustainable

Galvanized steel coils reduce maintenance and replacement expenses due to their longevity. Additionally, they are 100% recyclable, aligning with eco-friendly manufacturing practices and sustainability goals.

5. Wide Applicability

From roofing sheets and automotive panels to electrical cabinets and agricultural equipment, this product adapts to multiple sectors. Its lightweight yet robust nature also supports energy-efficient designs in modern infrastructure.

6. Certified Quality Assurance

Produced under strict international standards (e.g. ASTM, JIS, or EN), each coil undergoes rigorous quality checks to guarantee dimensional accuracy, coating adherence, and defect-free performance.

About Us

Founded in 1996, Qingzhou Jianfu Gear Co., Ltd is an enterprise focusing on the research and production of automotive spiral bevel gear. Company is located in the development zone of Qingzhou City, Shandong Province, covering an area of 200 mu, with more than 1000 employees. Jianfu Gear Co., Ltd. mainly produces automobile rear axle gear, loader gear, etc., with an annual output of 1 million sets of various arc gears.

Company has a strong team in technology and advanced processing equipment, including more than 560 sets of accurate processing equipment, 36 world advanced level of the United States Gleason gear production lines, 5 Olinkon high gear production lines, 5 forging production lines, 8 advanced automatic heat treatment production lines and the domestic advanced level of gear testing equipment. The support of these devices and technology enables company to ensure the high assembly quality and durability of the gears, which are widely used in the field of automotive manufacturing and have won wide recognition from customers.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.