Welcome!

cold rolled galvanized steel strip wholesale

Product Description

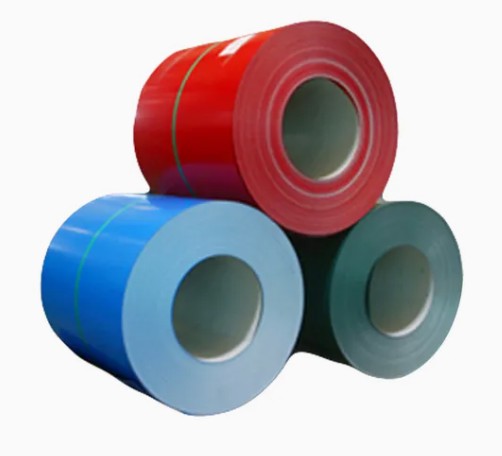

Cold-rolled galvanized steel strip is an industrial material that is made by rolling hot-rolled steel strip below the recrystallization temperature at room temperature and coating it with a layer of zinc to achieve the purpose of corrosion resistance and aesthetics.

The production process of cold-rolled galvanized steel strip includes several key steps:

The raw material of cold-rolled galvanized steel strip is hot-rolled steel strip, which is a material that is rolled below the recrystallization temperature at room temperature. Through the galvanizing treatment, that is, a layer of zinc is covered on the surface of the steel strip, which not only prevents steel corrosion and thus prolongs its service life, but also provides a good appearance. The galvanizing treatment can be achieved by hot-dip galvanizing, which can make the coating uniform, have strong adhesion and a long service life. In this process, the steel strip substrate undergoes complex physical and chemical reactions with the molten plating solution to form a corrosion-resistant and tightly structured zinc-iron alloy layer. This alloy layer is integrated with the pure zinc layer and the strip steel substrate, greatly enhancing the corrosion resistance of the material.

Cold-rolled galvanized steel strip can be provided in the form of steel plate or steel strip. The steel strip delivered in sheets is called steel plate, also called box plate or flat plate; the steel strip delivered in long lengths is called steel strip, also called coil. Due to its good corrosion resistance and aesthetics, cold-rolled galvanized steel strip is widely used in various fields, including construction, home appliances, automobile manufacturing, etc., involving almost all industries that require the use of steel.

Characteristics of high-density zinc cold-rolled steel strip

1. Excellent anti-corrosion performance: On the basis of ordinary cold-rolled steel strip, high-density zinc cold-rolled steel strip has a zinc layer added to the surface, which has excellent anti-corrosion performance and can be used for a long time in harsh environments.

2. High aesthetics: The surface of high-density zinc cold-rolled steel strip is coated with a zinc film, which has the characteristics of high gloss, smooth surface, high aesthetics, and can maintain a long-term novel appearance.

3. Strong wear resistance: After the surface of the high-density zinc cold-rolled steel strip is coated with a zinc film, its hardness and wear resistance are improved, it can withstand greater pressure and weight, and has higher strength and toughness.

4. Low cost: Compared with other materials, the cost of high-density zinc cold-rolled steel strip is relatively low, which can meet the needs of large-scale production.

The difference between galvanized steel strip and cold-rolled steel strip

1. Definition and process characteristics

Galvanized steel strip is a metal product with a corrosion-resistant zinc layer formed on the surface of cold-rolled steel strip as the base material. Cold-rolled steel strip refers to a steel plate made by cold-rolling hot-rolled steel plates at room temperature.

The production process of galvanized steel strip includes multiple steps such as steel strip surface treatment, zinc dipping, and forming. The production process of cold-rolled steel strip is to first make a steel billet through hot rolling or continuous casting technology, and then process it into a steel plate through cold rolling.

2. Physical properties

The outer zinc layer of galvanized steel strip can enhance the hardness and strength of the steel strip, and has good electrical conductivity, thermal conductivity and wear resistance. However, since the cold-rolled steel strip has not been heat-treated, its grains are small and dense, with good hardness and strength, but its mechanical properties are not as good as those of galvanized steel strip.

3. Mechanical properties

Since the outer zinc layer of galvanized steel strip has a high hardness, its performance in hanging heavy objects, bending, and cutting is very good, and the zinc layer also has good ductility and is not easy to crack and peel off. The mechanical properties of cold-rolled steel strip are relatively weak, and it is easily deformed and damaged by external forces.

IV. Corrosion resistance

One of the advantages of galvanized steel strip is its corrosion resistance. The zinc layer can effectively isolate air and moisture, thereby protecting the substrate from corrosion. At the same time, the zinc layer can also self-repair, reducing maintenance costs. However, cold-rolled steel strip is prone to oxidation and rust because it has no coating protection.

Application range

1. Packaging industry: High-density zinc cold-rolled steel strips are widely used in various packaging materials, such as wood, steel, stone, etc., which can protect items from damage and corrosion.

2. Construction industry: High-density zinc cold-rolled steel strips can be used in the production of building structures, steel components, roof panels, wall panels and other materials, with the advantages of corrosion resistance, wear resistance and beauty.

3. Automobile manufacturing: High-density zinc cold-rolled steel strips can be used as materials for automobile parts, widely used in car bodies, doors, roofs, engine hoods and other parts, and are indispensable materials in the field of automobile manufacturing.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.