Welcome!

cold rolled stainless steel strip producers

Product Description

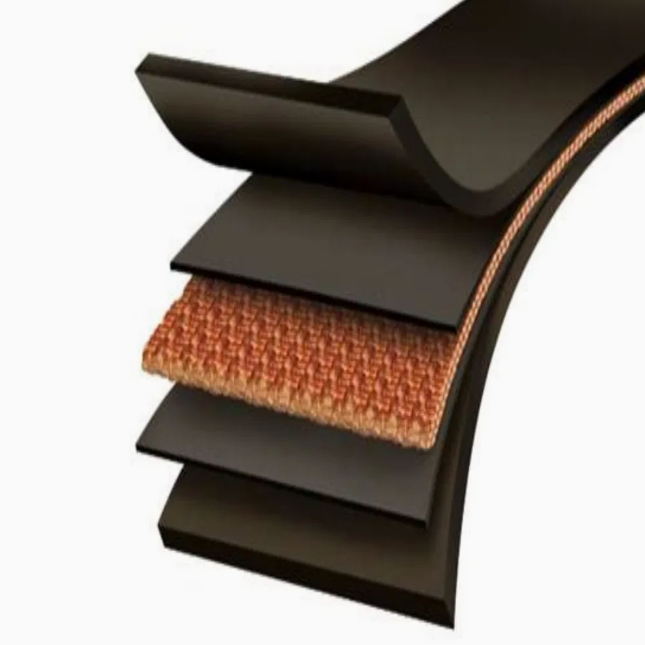

Cold rolled strip steel refers to hot rolled strip steel and steel plate, which are rolled into strip steel and thin plate at room temperature by cold rolling mill. The general thickness is 0.1-3mm and the width is 100-2000mm. Cold rolled strip or plate has the advantages of good surface finish, good flatness, high dimensional accuracy and good mechanical properties. Usually the products are rolled, and a large part of them are processed into coated steel plates.

Products and uses of cold-rolled strip steel

There are many varieties of cold-rolled strip steel products, and the production process is also different. It can be used in industrial sectors such as machinery manufacturing, automobile manufacturing, locomotives and vehicles, building structures, aerospace rockets, light industry and food, electronic instruments and household appliances.

When the thickness of cold-rolled strip steel is less than 0.2 mm, it is called ultra-thin strip steel or foil, and is rolled using a multi-roll mill. Due to the wide variety of product specifications, high dimensional accuracy, good surface quality, and better mechanical and process properties than hot-rolled strip steel, cold-rolled strip steel is widely used in various industrial fields. The surface quality of cold-rolled strip steel is extremely high, smooth and shiny, and it can meet a variety of application requirements without additional surface treatment. Whether it is household appliances, automobile manufacturing or the construction industry, cold-rolled strip steel plays a vital role.

The advantages of cold-rolled strip steel mainly include precise dimensions, uniform thickness, superior surface quality, good mechanical and process properties, and the ability to achieve high-speed rolling and full continuous rolling, with high production efficiency.

Precise dimensions and uniform thickness of cold-rolled strip products are one of its significant advantages. Compared with hot rolling, cold rolling can obtain thinner strips, superior product quality, and good mechanical and process properties. In addition, high-speed rolling and full continuous rolling can be achieved during the production process of cold-rolled strip steel, which not only improves production efficiency, but also makes cold-rolled strip steel have extremely high application value in industrial production. These advantages of cold-rolled strip steel make it an indispensable material in all walks of life, especially where high precision and high surface quality are required, cold-rolled strip steel is the material of choice

The production process of cold-rolled strip steel includes raw material preparation, heating, rolling, cooling, finishing and other links, as follows

1. Select suitable raw materials, such as carbon steel, low alloy steel, stainless steel, etc.

2. The raw materials are hot-rolled to become steel plates with a thickness of about 2~6mm, and then treated with boiler pickling, mechanical rust removal and other treatments.

3. Remove oxides, rust layers, oil stains and other impurities on the surface of the steel plate, and pickle by immersion or spraying.

4. Send the pickled steel plate to the cold rolling mill for cold rolling to press out the required thickness, width, flatness and other parameters.

5. After the production of cold-rolled strip steel is completed, it is cut to length, rolled into rolls and other subsequent processing to meet market demand.

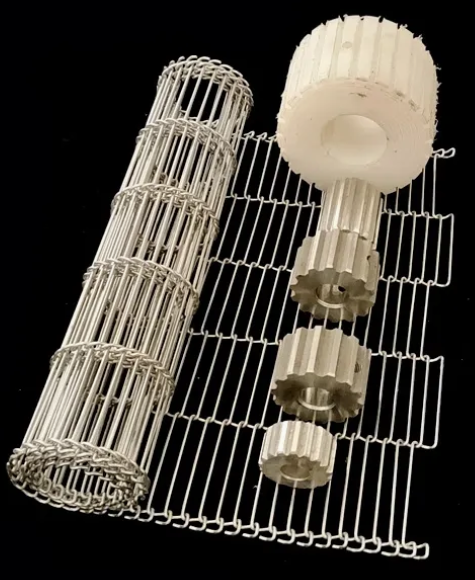

The production equipment of cold-rolled strip steel includes

1. Cold rolling mill is used to perform multiple passes of rolling on the heated steel plate to make it thinner and achieve the required dimensional accuracy and performance.

2. Continuous heating furnace is used to heat the raw steel plate to the rolling temperature.

3. Straightening machine is used to straighten the rolled steel plate.

4. Shearing machine is used to cut the steel plate to a fixed length.

5. Packing machine is used to pack the cold-rolled strip steel into a roll for easy transportation and storage.

Recommended Products

Recently Viewed

Contact Us

Qingzhou Jianfu Gear Co., Ltd.