Welcome!

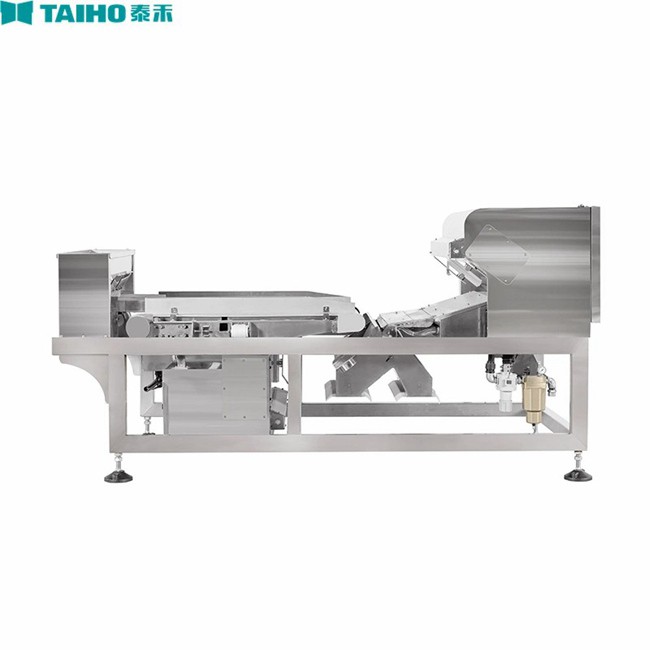

Factory Price Sorting Corn Seeds Nuts Sesame Rice Wheat Color Selection Machine

Product Description

After the material enters the color sorter, it is first evenly distributed on the vibrating conveyor belt, and then the material moves under the photoelectric sensor through the conveyor belt. Sensors detect the color, shape, size, and other characteristics of materials through photoelectric effect, and compare them with preset sorting standards. When defective products or impurities are detected in the material, the control system will immediately activate the removal device to separate the defective products or impurities from the material. Finally, high-quality and defective products are transported to different discharge ports to complete the sorting process.

In addition to the basic color selection function, some high-end grain color selection machines also have multiple functions such as stone removal, impurity removal, and grading, which can meet the needs of different users. Grain color sorter usually adopts a full-color touch screen operation interface with user-friendly design, making the operation more convenient and easy to learn.

With the continuous improvement of food safety regulations and the increasing demand for food quality from consumers, the food color sorter market will continue to maintain steady growth. In the future, food color sorting machines will pay more attention to the development direction of intelligence, automation, and efficiency, providing more advanced and reliable solutions for the food processing industry. At the same time, domestic color sorting machine enterprises will continue to strengthen technological innovation and product upgrades to enhance their competitiveness in the international market.

Food color sorter has a wide range of applications in multiple fields, including but not limited to:

Grain processing: such as rice, wheat, corn, etc., color sorting machines can effectively remove discolored grains, diseased grains, insect eaten grains, etc.

Fruit and vegetable processing: During the processing of fruits and vegetables, color sorting machines can remove defects such as insect holes, rotten fruits, and decay, improving the quality and appearance of the products.

Nuts and dried fruits: The color sorter can remove impurities, insect shells, mold, etc. from nuts and dried fruits, improving product quality.

Seafood: Used to remove impurities, shells, spines, etc. from seafood, and improve the hygiene and safety of products.

The food color sorter uses high-precision sensors and image processing technology to perform spectral analysis and image recognition on food. When food materials pass through the detection area of the color sorter, sensors will capture information such as the color, shape, size, etc. of the food and compare it with preset standards. If food that does not meet the standards (such as discolored particles, impurities, defective products, etc.) is detected, the color sorter will immediately activate the removal device to remove these unqualified foods from the production line.

Recommended Products

Recently Viewed

Best Selling Coffee Bean Hazelnut Cardamom Processing Colour Sorting Machine

Best Selling Coffee Bean Hazelnut Cardamom Processing Colour Sorting Machine High Quality Tea Color Sorter Tea Leaves Processing Grading Machine Colour Sorting Machinery

High Quality Tea Color Sorter Tea Leaves Processing Grading Machine Colour Sorting Machinery Wholesale Price Coffee Bean Hazelnut Cardamom Processing Colour Sorting Machine

Wholesale Price Coffee Bean Hazelnut Cardamom Processing Colour Sorting Machine Best Selling Sorting Corn Seeds Nuts Sesame Rice Wheat Color Selection Machine

Best Selling Sorting Corn Seeds Nuts Sesame Rice Wheat Color Selection Machine Automatic Bean color sorter, peanut and mung bean color sorter

Automatic Bean color sorter, peanut and mung bean color sorter

Contact Us

Hefei Taihe Intelligent Technology Group Co., Ltd.